What are the lime grinding machines

LIMESTONE MILLS CRUSHERS Williams Crusher

Williams Direct Injection Roller Mills are used as limestone grinding machines and can grind to very exact particle sizes that are required for efficient SO2 removal These limestone mills are designed to operate at 3 to 4 PSI (02 to 03 bar) and 250°F (120°C) to inject the limestone We design our machines with you in mind Our Ripshear® Compact SlowSpeed Compact SlowSpeed ShreWhat is a Limestone Grinding Machine? A limestone grinding machine is a piece of equipment designed to grind limestone into a fine powder It is used in various industries, including How does Limestone Grinding Machine Work and What to 2023年12月8日 Coarse crushing equipment: The commonly used equipment is jaw crusher In the limestone crushing production line, the coarse crushing equipment can crush the large pieces of limestone mined into stones of 125 Limestone crushing technology and equipment

.jpg)

What Limestone Machinery Is Used In Limestone Processing?

2023年12月19日 Here are some types of machinery commonly used in limestonerelated processes: 1 Mining Equipment: Purpose: Creates boreholes in the rock for the placement of 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freelyLimestone Ultrafine Mill Machine SBM Ultrafine 2024年1月18日 Limestone is the primary raw material for manufacturing cement, lime, and carbide and is an essential flux limestone in the metallurgical industry Highquality limestone, after ultrafine grinding, is widely used in the How to choose a limestone grinding mill2022年8月26日 In the above mentioned limestone grinding plant, grinding mill is the core equipment that directly decides the quality and fineness of final limestone powder And the efficiency of grinding mill also affects the effect of the whole Which Grinding Mill Is Suitable For Processing

.jpg)

What is Limestone Grinding Mill SBM Mill

2023年5月15日 A limestone grinding mill is a machine that grinds and powderizes limestone It is very useful in the manufacture of cement, glass, steel and other industrial products that require finely ground limestone Limestone 2024年10月16日 The limestone grinding mill uses the principle of mechanical crushing to grind large pieces of limestone into fine particles It is an important equipment for deep processing Limestone Grinding Mill, Limestone Mill,Limestone Grinding MachineLimestone is not only the main component in cement raw material Owing to its particular characteristics, the separate grinding of limestone in our Pfeiffer machines has been a routine Limestone mills for all requirements Gebr Pfeiffer2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine

Classification and application of stone grinding mill machine

2024年10月12日 I Working Principle of Stone Grinding Mill Machines Stone grinding machines mainly rely on the squeezing and grinding action between the grinding roller and the grinding ring to achieve the crushing of stones The working process is roughly as follows: 1 Material entry The stone material to be ground enters the main cavity of the grinding For fine grinding lime hydrate lumps, grinding circuits comprising ball mills and separators are provided Instead of separators, screening machines are used in case of coarse grinding The fineness of the products can be set within wide Quicklime preparation Gebr PfeifferA grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformationWhat Is Grinding Machine? Definition, and Types The 2022年4月8日 Surface grinding machines are implemented to grind the flat surface of workpieces, utilized to finishing plate or blockshaped workpieces to high precise accuracy This type of grinders is widely used in the mold and die industry because it excels at machining metal plates They basically consist of a grinding wheel head, grinding wheel spindle, table on which Machining 04: What is a grinding machine? SEISANZAI Japan

.jpg)

4 Types of Grinding Machine and How to Choose Yours

Now that you know what are the common types of grinding machines, follow these key considerations to make an informed decision 1 Define Your Applications: Clearly outline the primary applications for which the grinding machine will be used Different machines excel in different tasks, so understanding your specific needs is crucial2023年5月30日 A grinding machine’s electric motor provides rotational motion power to the grinding wheel via a belt and pulley system So, when we turn on the electric motor, it rotates at a specific angular velocity (10015000 RPM, depending on the grinding machine), and the grinding wheel begins to turn as well, and we carry out the operation Grinding Machines Overview, Working, Types, and UsesHere’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas 1 Surface Grinders: A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table 2 Cylindrical Grinders: A cylindrical grinder is used for shaping the outside of a workpiece 3What Is Grinding Machine? Definition, and Types Mechdaily2024年7月17日 Internal Cylindrical Grinding: Machines the internal holes of the workpiece, commonly used for bearings and cylinders Centerless Grinding Does not require clamping the workpiece Instead, it grinds the workpiece through relative motion between the grinding wheel and the guide wheel Centerless grinding is suitable for mass production of small What is Grinding? Understanding the Basics and Applications

.jpg)

Chapter 17: Grinding Methods and Machines American

2020年6月29日 Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industry Grinding 2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and Limestone crushing technology and equipment2021年9月16日 A grinding machine is a strong machine that is utilized to eliminate material from the outer layer This machine includes a pivoting cutting instrument set against a fixed workpiece, called the rotating wheel, which is What are the Different Types of Grinding 2024年4月13日 A concrete grinder grinding machine typically consists of a rotating disc or wheel, often made of diamond or other hard materials, that grinds away the surface layer of the concrete This grinding action is achieved by the friction between the abrasive disc and the concrete surface The operator guides the machine over the concrete surface The Ultimate Guide To Using A Concrete Grinder Grinding Machine

.jpg)

Surface Grinding: A Guide to the Process and Precision okdor

2024年1月11日 Innovations in grinding wheel materials, such as using cubic boron nitride in CBN grinding wheels, enhance the machine’s ability to grind hard materials while maintaining a flat edge and desired surface quality The development of more efficient and precise grinding machines continues to address the evolving challenges in surface grinding2024年11月21日 For the portable grinder, the rotor is inside the grinding machine, and the power switch is located beside the handle of the grinder So, the switch must be pressed before the grinder works For grinders that feature an electric motor, the motor rotates at a certain rpm (from 150 to 1500 RPM, it may change according to the type of grinding What is Grinding Machine? its Diagram and How it Works2021年1月16日 Your Single Disc Surface Grinding Machine will look like a horizontal spindle surface grinding machine albeit smaller in size since it does not need a reciprocating or circular table The grinding action in your machine takes place by the abrasive particles on the face of the grinding wheel You will be able to give the feed (depth of cut) by moving the wheel headSurface Grinder Types of Grinders How They Work Fine 2018年2月17日 The grinding machine is a machine tool used to carry out finishing operations, often the grinding machine is characterized by a great structural rigidity As the name suggests, the grinding machine is used to perform grinding operations using tools called grinding wheels characterized by a fine and extremely hard grainHow does a grinding machine work and what are the

Turmeric Grinding Machine For Home – Easy To Use

5 天之前 Our turmeric grinding machine for home is ideal for domestic purposes Also, if you have a small spice plant then this is the perfect addition Dry Ginger, Lime Stone, Coal, Waterchest Nut, Dry Dates, Besan, etc Can’t Grind: Chili, Grains or Not Oily or Wet Materials Electric Motor: 75 HP Three Phase Call Us WhatsApp us Description 2022年11月28日 The grinding wheel extends into the hole for grinding At this time, the outer circle is used as the positioning reference to ensure that the inner circle and the outer circle are concentric Centerless internal grinding is usually used to grind the inner raceway of the bearing ring on the special grinding machine for the bearing ringWhat is Grinding Process How It Works Different Types 2021年7月3日 Creep feed grinding is a slow, onepass operation that makes a deep cut of up to one inch in steel materials at low table speeds between 05 and 1 ipm It is not suitable for conventional grinding machines, but for those which are compatible with it, it offers high productivity and cost effectivenessMachining 101: What is Grinding? Modern Machine Shop1 天前 Whether crafting intricate components for the aerospace industry or ensuring the flawless finish of automotive parts, grinding machines play a critical role in achieving the desired level of accuracy and surface finish These versatile machines are essential in transforming raw materials into finely honed pieces, ready for assembly and use in An Introduction to the Types of Grinding Machines MFG

.jpg)

Market Prospects What Is A Grinding Machine?

2020年5月19日 Grinding machines produce flat, cylindrical, and other surfaces by means of highspeed rotating abrasive wheels A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting There are 2023年5月5日 A grinding machine consists of the following parts: 1 Base – The base of the grinding machine supports the other parts of the machine It is made of cast iron and rests on a flat foundation 2 Column – The column is a Grinder Machine – Working, Types, Applications, Address Shiv Shakti Mechanicals H 459460, H1463464, 2nd Phase, Sarna Dungar Industrial Area, Jhotwara Extension, Jaipur , Rajasthan, India Get DirectionsShiv Shakti Mechanicals Manufacturer of Lime Plant Hydrated Lime 2024年3月13日 The grinder machine was invented by John Wilkinson in 1775 He developed the first grinding machine, which was primarily used for the precision boring of cannon barrels Later, Charles Norton made significant advancements in the late 19th century, leading to the development of modern grinding machines used in various industrial applications todayWhat is Grinding Machines: Different Types, Uses, and Price

.jpg)

Necessary Matters About Limestone Powder Grinding

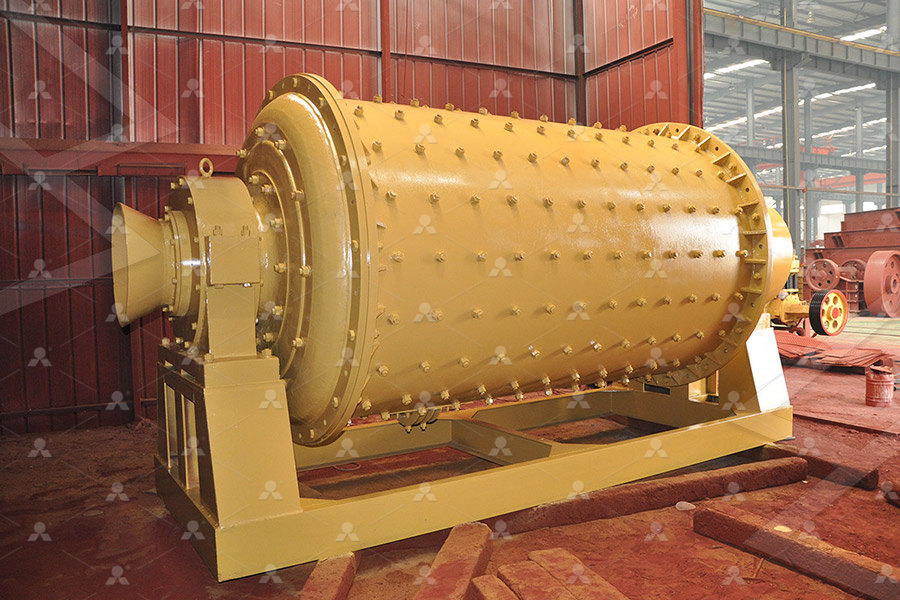

2023年2月28日 3 types of limestone grinding machines After crushing, grinding is an effective size reduction process to obtain limestone powder of various fineness The popular limestone grinding mills are Raymond mill, HGM ultrafine mill, and threering mediumspeed micro mill Raymond mill Get Latest Price2024年11月26日 The flexible Spiro F7 finegrinding machine is ideal for creating precise flat surfaces on workpieces made from a wide variety of materials Memory for 192 programs; Rigid machine concept; Userfriendly, thanks to visualprocess control Workpiece specifications; Wheel diameter: 720 mm: Ring width: 200 mm: Maximum pressure:Supfina Fine GrindingLimestone powder can produce quicklime by calcination Quicklime can be widely used for desulfurization in power plants, and after adding water treatment to get hydrated lime By mixing hydrated lime, lime slurry and lime paste can be obtained, which are used for coating materials and processing materials of brick and tile adhesivesLimestone Mill for Limestone Powder Grinding Limestone Crushing2021年4月16日 Grinding hand tools A die grinder is a highspeed rotary tool that is typically powered by compressed air The tool has a smalldiameter abrasive bit that rotates to get the job done Check out Choosing the Right Air Die Grinder for more information and some recommended models Angle grinders are also abrasive hand tools Unlike die grinders, Intro to Grinding Methods, Machines and Tools

AusIMM – Leading the way for people in resources

%PDF16 %âãÏÓ 4215 0 obj > endobj 4235 0 obj >/Encrypt 4216 0 R/Filter/FlateDecode/ID[87C03FABF6FB2246BC4F9AB649B4B217>]/Index[4215 26]/Info 4214 0 R/Length 101 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine 2024年10月12日 I Working Principle of Stone Grinding Mill Machines Stone grinding machines mainly rely on the squeezing and grinding action between the grinding roller and the grinding ring to achieve the crushing of stones The working process is roughly as follows: 1 Material entry The stone material to be ground enters the main cavity of the grinding Classification and application of stone grinding mill machineFor fine grinding lime hydrate lumps, grinding circuits comprising ball mills and separators are provided Instead of separators, screening machines are used in case of coarse grinding The fineness of the products can be set within wide Quicklime preparation Gebr Pfeiffer

What Is Grinding Machine? Definition, and Types The

A grinding machine, often shortened to grinder, is one of the power tools or machine tools used for grinding, it is a type of machining using an abrasive wheel as the cutting tool Each grain of abrasive on the wheel’s surface cuts a small chip from the workpiece via shear deformation2022年4月8日 Surface grinding machines are implemented to grind the flat surface of workpieces, utilized to finishing plate or blockshaped workpieces to high precise accuracy This type of grinders is widely used in the mold and die industry because it excels at machining metal plates They basically consist of a grinding wheel head, grinding wheel spindle, table on which Machining 04: What is a grinding machine? SEISANZAI JapanNow that you know what are the common types of grinding machines, follow these key considerations to make an informed decision 1 Define Your Applications: Clearly outline the primary applications for which the grinding machine will be used Different machines excel in different tasks, so understanding your specific needs is crucial4 Types of Grinding Machine and How to Choose Yours2023年5月30日 A grinding machine’s electric motor provides rotational motion power to the grinding wheel via a belt and pulley system So, when we turn on the electric motor, it rotates at a specific angular velocity (10015000 RPM, depending on the grinding machine), and the grinding wheel begins to turn as well, and we carry out the operation Grinding Machines Overview, Working, Types, and Uses

What Is Grinding Machine? Definition, and Types Mechdaily

Here’s a look at some of the most common types of precision grinding machines from Maximum AdvantageCarolinas 1 Surface Grinders: A surface grinder consists of an abrasive wheel, a chuck (a workpiece holding device), and a rotary table 2 Cylindrical Grinders: A cylindrical grinder is used for shaping the outside of a workpiece 32024年7月17日 Internal Cylindrical Grinding: Machines the internal holes of the workpiece, commonly used for bearings and cylinders Centerless Grinding Does not require clamping the workpiece Instead, it grinds the workpiece through relative motion between the grinding wheel and the guide wheel Centerless grinding is suitable for mass production of small What is Grinding? Understanding the Basics and Applications2020年6月29日 Grinding, or abrasive machining, once performed on conventional milling machines, lathes and shapers, are now performed on various types of grinding machines Grinding machines have advanced in design, construction, rigidity and application far more in the last decade than any other standard machine tool in the manufacturing industry Grinding Chapter 17: Grinding Methods and Machines American