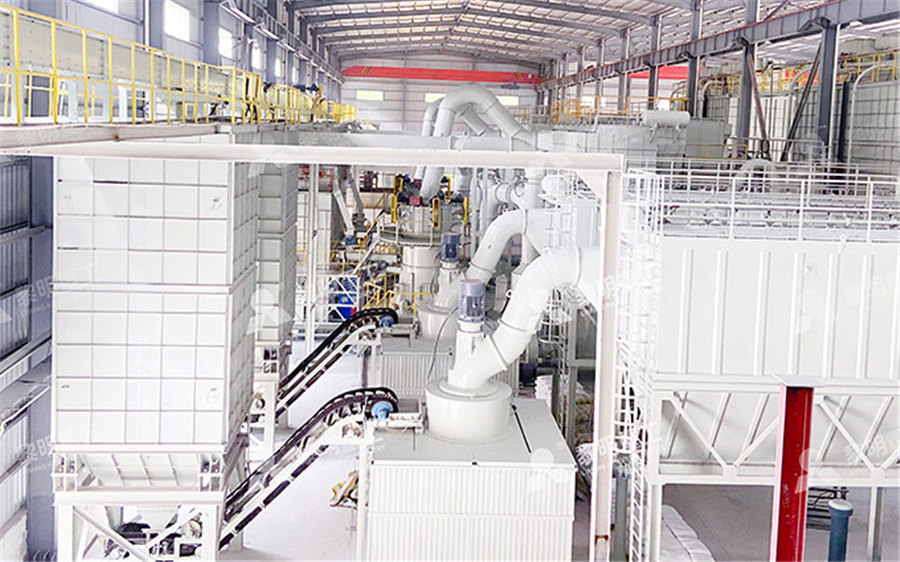

Working diagram of airflow grinding machine

How to operate an air classifier mill to meet your fine grinding goals

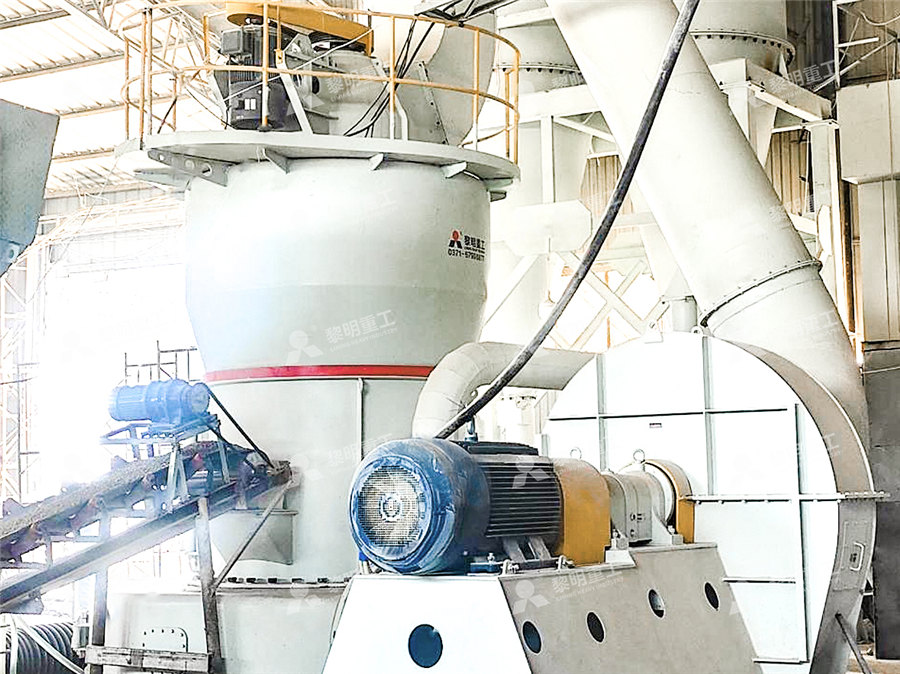

An air classifier mill applies impact grinding and air classification in one step The mill uses airflow to convey feed material to the mill’s grinding chamber, classifies the material into fine An air classifier mill, also known as an air classifying mill, uses airflow to separate particles by size The mill consists of a grinding chamber, a classifying wheel, and a fan The raw material to be ground is fed into the grinding chamber, which is Air Classifier Mills for Precise Particle Sizing AtritorDodds et al [6] proposed an overall model of the grinding and classification in an air jet mill with an integrated classifier The mill is divided into a perfectly mixed grinding zone, a transport zone with prevailing plug flow and a classification (PDF) Grinding in an air classifier mill Academia2011年7月25日 The mill is divided into a perfectly mixed grinding zone, a transport zone with prevailing plug flow and a classification zone, characterized by a grade efficiency curve While Grinding in an air classifier mill — Part I: Characterisation of the

Air Classifying Mill

The Mikro ACM® Air Classifying Mill is an air swept mechanical impact mill with a dynamic air classifier designed to grind an extensive range of materials down to a D97 of 20 microns The 2018年10月1日 A grinding machine or grinder is an industrial power tool that uses an abrasive wheel for cutting or removing the material It is a process of metal cutting by using a rotating abrasive wheel from the surface of the Grinding Machine: Types, Parts, Working Operations The document discusses 14 types of grinding machines including bench, hand, pedestal, portable, flexible, and precision grinders Precision grinders include cylindrical, plunge cut, form, 14 Types of Grinding Machines (Working, Diagram PDF)Atlas Copco Turbine Grinders give you twice the power with half the weight and are impossible to stall with the right installation! Atlas Copco ́s range covers all, you can rely on maximum Grinders Sanders Atlas Copco

Grinding Machine Guide CNC Machine Tools Okuma

Download the Okuma Grinding Machine Guide to learn what a grinding machine is, how it works and why you need one on your shop floorTypes of Grinding Machine Grinding machines are broadly classified into two categories which are further classified as follows: – A) Rough Grinder/Grinding Machines Rough grinders are those types of grinders which are used to the Types of Grinding Machine: Parts, Working Principle 2020年7月4日 Planer Machine is a machine in which unwanted material is cut from the workpiece to produce a flat surface on the workpiece Unlike Shaper Machine, in this machine, more than one tool can be set and perform an Planer Machine: Definition, Parts, Working 2023年10月6日 A cylindrical grinding machine is a vital tool in precision machining, known for its exceptional ability to produce finely finished cylindrical components with remarkable accuracy and consistency These machines play Cylindrical Grinding MachineDiagram, Parts,

AirJet Loom: Working Principle, Data Processing and Advantages

US Pat No 4,606,152 illustrates a method and apparatus for grinding or buffing a metal reed of an air jet loom by manually moving a buffer along the tunnel while the reed is positioned and the compressed airflow is used to pull the frictional traction force of the weft Tubular Compactor Machine: Parts, Functions, Working 2023年8月1日 In this article, you learn what is planer machine? Its diagram, types, parts of planer machine, working principle, and PDF of this article What is Planer Machine? Contents show The planer machine is similar to a shaper machine It Planer Machine Parts, Types, Working principle with PDFBench Grinding Machine: Parts, Working What is Bench Grinding Machine? It is the most common type of grinding machine found in tool rooms and workshops It is used to sharpen the tools, grind the workpiece surface and remove roughness Small items in the labs are machined using a bench grinder Parts of Bench Grinding Machine MotorGrinding Machine: Definition, Types, Parts, Working Operations2014年5月29日 There are numerous types of grinding machines in Engineering field, which are used to fulfil the requirements We are interested to introduce automatic pneumatic system in especially in grinding machine and also grinding operation The main function of automatic pneumatic grinding machine is to cut thin and soft metals by pneumatic powerAutomatic Pneumatic Grinding Machine: Working Principle and

.jpg)

Types of Internal grinding machine with Diagram Explained

Broadly there are three different types of internal grinding machine as follows: 1 Chucking type internal grinder 2 Planetary internal grinder 3 Centreless internal grinder Read more : Types of Grinding Machines – LearnMech; Types Of Surface Grinding machine with Diagram Explained Types of Cylindrical grinding machine with Diagram In the plunge grinding machine the grinding wheel moves radially towards the substance 4 Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the substance through the grinding wheel all at once This machine greatly reduces the manufacturing time 5 Centerless Grinding Machine The centerless grinding Cylindrical Grinding Machine: Types, Process Working Principle2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining Guide to Centerless Grinding Machine: Advantages, Working Criteria for the Selection of Grinding Machines for the Grinding Operation in Industries Finding Ideal Kind of Machine It is the most essential steps for the selection of grinding machine It totally affects the cost and time in process Types of Grinding Machine: Parts, Working Principle

DC Machine – Construction, Working, Types and

Working of DC Machine The working principle and operation of a DC machine is based on an effect when a current carrying conductor coils laying in a magnetic field, Automatic UPS / Inverter Connection Diagram to the Home Panel Download scientific diagram General structure of grinding machine from publication: Working parameter optimization of strengthen waterjet grinding with the orthogonalexperimentdesignbased General structure of grinding machine Download The hydraulic circuit for surface grinding machine utilizes a power pack to supply pressurized oil, one pilotoperated direction control valve which decides the direction of the flow of pressurized oil and a doubleacting cylinder with the double piston rodHydraulic Circuit for Surface Grinding Machine Engineering Arena2014年10月25日 12 • This grinding machine with all working motions is shown in Fig a The grinding operation is similar to that of face milling on a vertical milling machine In this machine a cup shaped wheel grinds the work piece over its full Surface grinding machine PPT SlideShare

.jpg)

Air Classifying Mill

Mikro® ACM Model Rotor Power (HP) Classifier Power (HP) Max Rotor Speed (RPM) Approx Air Flow (ft3/min) Scale Up Factor Optional Designs Configurations Coaxial Drive Independent Drive Easy Access/ Easy Clean High Speed Rotor Pressure Shock Resistant EACM Superfine Configuration High Temperature Operation2023年8月21日 Working Principle of Planer Machine Fig 1: Planer machine In a Planer Machine, the workpiece is securely fixed to the machine table, while a singlepoint cutting tool is appropriately held in the tool post attached to the reciprocating ram The reciprocating motion of the ram is achieved through a quick return motion mechanism, ensuring smooth backand Planer Machine: Diagram, Parts, Working, Types, Advantages, Uses2021年8月27日 The grinding wheel is the most important and unique part of the electrochemical grinding machine It is connected to the negative terminal of the power supply and acts as the cathode The grinding wheel is made of insulating materials such as diamond and aluminum oxide The wheels rotate and increase the flow of the electrolyteElectrochemical Grinding: Definition, Parts or Construction, Working 2023年10月1日 3 Grinding Machine : The machine structure provides the static and dynamic constraints between the tool and the workpiece Type of machines to be selected depends upon the type of operations to be performed A perfectly designed grinding machine should experience less vibrations and provide high accuracy movementsWhat is Grinding? Process, Machine, Parts ElectricalWorkbook

Effects of air pressure, mass flow rate on grinding forces

Download scientific diagram Effects of air pressure, mass flow rate on grinding forces from publication: Experimental investigation on the influence of oil mist parameters on minimum quantity 2023年5月22日 Test rig—grinding installation with electromagnetic mill The grinding installation used in this research is shown in Fig 1Feed material is supplied with a screw feeder and enters the working Model and simulator of inlet air flow in grinding installation with The main parts of lathe machine are as follows:Line Diagram: Main Parts of Lathe Machine 1 Bed 2 Head Stock 3 Main Spindle 4 Tail Stock 5 Working Principle of lathe machine Grinding is the operation of removing Lathe MachineIntroduction,Working, 9 Parts,Types, Introduction A longterm objective in comminution science and technology is the realistic modelling and design of grinding machines independent of the respective material under consideration One step in this direction is the development of (PDF) Grinding in an air classifier mill Academia

.jpg)

Grinding Machine Definition,Working,Parts,OperationTypes

Grinding Machine A grinding is metal cutting operation which is performed by means of a rotating abrasive wheel that acts as a tool; These are mostly used to finish workpieces which must show a high surface quality, accuracy of shape and dimension Mostly, it is finishing operation because it removes material in very small size of chips 025 – 05 mm2021年8月11日 As a Wheat Milling Machine Plant manufacturer, PINGLE share it with everyone The operation of the flour grinding machine adopts blade cutting and highspeed air impact and the twolayer destruction function of collision is integrated, and the particle sorting process can be completed together The operating principle of the flour mill: During the blade Flour Mill Working Principle PINGLE Hebei Pingle Flour 2023年2月22日 Read also: ElectronBeam Machining (EBM): Working Principle, Advantage, Limitation and Design A DC power supply in the range of 525 volt Maintains current densities, which for most of the applications are 158 A/mm2 of the active machined surface Machines having current capacities as high as 40,000 A and has low has 5 AR availableElectrochemical Machining (ECM): Process, Working Diagramcement manufacturing process by tizita moges , selamu abule dereje endalamaw if you need this guide and all other useful excel sheets which will make you master the production , process , maintenance activity in your cement plant kindly click hereCement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Tool and Cutter Grinder: Diagram, Parts, Types, Operation and Use

2023年9月27日 Characteristics of Tool and Cutter Grinder The tool cutter grinding machine exhibits the following notable characteristics: Maximum Wheel Diameter Holding: This machine has the capability to accommodate the largest wheel diameter suitable for the grinding process Maximum Job/Workpiece Height: It can grind workpieces with a maximum height, ensuring 2024年5月29日 The method is employed to machine hard and brittle materials that are either electrically conducting or nonconducting Analysis of the mechanism of material removal by the USM process indicates that it may sometimes be called Ultrasonic Grinding (USG) Read Also: 16 Common Types of Welding Defects [Causes Remedies] Parts of Ultrasonic MachiningUltrasonic Machining: Diagram, Working Principle, Applications2022年7月4日 As you can see the above diagram of Shaper machine, The tool is hold by Ram and workpiece is fixed over table When we switch on the power the ram reciprocates with respect to the table that means the cutting tool cuts workpiece material in the forward direction and when moving return there is no cutShaper Machine: Definition, Parts, Working Principle, Types, Types of Grinding Machine Grinding machines are broadly classified into two categories which are further classified as follows: – A) Rough Grinder/Grinding Machines Rough grinders are those types of grinders which are used to the Types of Grinding Machine: Parts, Working Principle

Planer Machine: Definition, Parts, Working

2020年7月4日 Planer Machine is a machine in which unwanted material is cut from the workpiece to produce a flat surface on the workpiece Unlike Shaper Machine, in this machine, more than one tool can be set and perform an 2023年10月6日 A cylindrical grinding machine is a vital tool in precision machining, known for its exceptional ability to produce finely finished cylindrical components with remarkable accuracy and consistency These machines play Cylindrical Grinding MachineDiagram, Parts, US Pat No 4,606,152 illustrates a method and apparatus for grinding or buffing a metal reed of an air jet loom by manually moving a buffer along the tunnel while the reed is positioned and the compressed airflow is used to pull the frictional traction force of the weft Tubular Compactor Machine: Parts, Functions, Working AirJet Loom: Working Principle, Data Processing and Advantages2023年8月1日 In this article, you learn what is planer machine? Its diagram, types, parts of planer machine, working principle, and PDF of this article What is Planer Machine? Contents show The planer machine is similar to a shaper machine It Planer Machine Parts, Types, Working principle with PDF

.jpg)

Grinding Machine: Definition, Types, Parts, Working Operations

Bench Grinding Machine: Parts, Working What is Bench Grinding Machine? It is the most common type of grinding machine found in tool rooms and workshops It is used to sharpen the tools, grind the workpiece surface and remove roughness Small items in the labs are machined using a bench grinder Parts of Bench Grinding Machine Motor2014年5月29日 There are numerous types of grinding machines in Engineering field, which are used to fulfil the requirements We are interested to introduce automatic pneumatic system in especially in grinding machine and also grinding operation The main function of automatic pneumatic grinding machine is to cut thin and soft metals by pneumatic powerAutomatic Pneumatic Grinding Machine: Working Principle and Broadly there are three different types of internal grinding machine as follows: 1 Chucking type internal grinder 2 Planetary internal grinder 3 Centreless internal grinder Read more : Types of Grinding Machines – LearnMech; Types Of Surface Grinding machine with Diagram Explained Types of Cylindrical grinding machine with Diagram Types of Internal grinding machine with Diagram ExplainedIn the plunge grinding machine the grinding wheel moves radially towards the substance 4 Creep Feed Grinding Machine The creep feed grinding machine eliminates a full chunk of the substance through the grinding wheel all at once This machine greatly reduces the manufacturing time 5 Centerless Grinding Machine The centerless grinding Cylindrical Grinding Machine: Types, Process Working Principle

Guide to Centerless Grinding Machine: Advantages, Working

2023年5月18日 A centerless grinding machine is a machine tool that uses CNC technology to grind the surface of a workpiece using grinding tools Most grinders use highspeed rotating grinding wheels for grinding, while a few use other grinding tools such as oilstones, abrasive belts, and free abrasives for processing, such as honing machines, ultraprecision machining