Vertical mill feed and discharge position

.jpg)

Chapter 18 Feed Milling Processes

The discs of an attrition mill are generally in a vertical position so that materials not capable of reduction can pass by gravity out of the grinding area 23 Roller Mills By the sudden release of pressure at the discharge end, the feed assumes a "puffed rice" texture like some breakfast 2017年9月11日 Due to the compact design and material transportation system of vertical roller mills (VRM), some important streams (total mill feed and discharge, dynamic separator feed and reject)(PDF) Performance Evaluation of Vertical Roller Mill in 2017年4月1日 Vertical roller mills (VRM) have found applications mostly in cement grinding operations where they were used in raw meal and finish grinding stages and in power plants Operational parameters affecting the vertical roller mill of a laboratory scale vertical stirred mill using a Bond ball mill An energybased population balance model was developed to analyze the response in product size resulting from changingPREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION FROM

Performance Evaluation of Vertical Roller Mill in Cement Grinding:

Among these technologies, vertical roller mills have an important position in cement industry Vertical roller mills are widely used for especially grinding of coal, cement raw materials,2022年5月31日 The vertical roller mill (VRM) is commonly used for secondary and tertiary crushing processes in numerous industries In this study, the discrete element method (DEM) Analysis of vertical roller mill performance with changes in material 2017年4月15日 This paper presents a numerical study on the particle conveying in a feed screw section of vertical rice mill based on the discrete element method The effects of key DEM study of particle conveying in a feed screw section of vertical At the discharge end of the conditioning chamber is a gate to restrict feed from immediately leaving and allows more time for moisture to be absorbed into the feed A chute or funnel usually guides moistureconditioned feed into the pellet (PDF) Feed Milling Processes Abu Rayhan

AMIT 135: Lesson 7 Ball Mills Circuits

The CenterPeriphery Discharge mill has feed reporting from both ends and the product discharges from the center bottom In all systems, the feed trunnion is smaller than the discharge trunnion to ensure a good flow and no backflow to Vertical milling machines are versatile tools in machining, offering operations like face milling for flat surfaces, end milling for features, drilling as a drill press, boring for hole enlargement, tapping for threading, and slotting for creating Milling Machine Working Principle And OperationsMinerals 2023, 13, 315 5 of 16 Figure 4 Pilot scale M20 and its internal structure (on the right) 22 Sampling of FullScale HIGMill and Pilot Tests of IsaMillPerformance Comparison of the Vertical and Horizontal Oriented 2019年4月16日 Production capacity of the feed mill is defined based on continuous processes in tonnes per 300 secondsor five minutes per hour would be needed tofill and discharge the mixer 55 minuteswould be net mixing time Selecting optimal mixer options in feed milling

.jpg)

An investigation of performance characteristics and

2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal MillFigure 37 Size analysis for a repeat experiment performed in a vertical mill shown as a function of grinding time for a single 595 +420μm feed size 71 Figure 38 Vertical mill geometry (left) and RockyDEM simulation of the vertical millPREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION FROM A VERTICAL 2017年2月13日 This should show the ball mill (feed, discharge and position of drive); Unit Flotation Cell or a Mineral Jig, if in circuit, and classifier Grinding Rods High carbon steel rods are recommended, hot rolled, hot sawed or sheared, to a length of 2″ less than actual length of mill taken inside the linersBall Mills 911Metallurgist

.jpg)

Vertical Mill – Power Feed – Blondihacks

2018年12月15日 Regular readers know I recently adopted a PM25MV vertical mill from Precision Matthews It has proven to be an excellent machine, and I recommend it highly to anyone I ordered it with the DRO and power feed options, because I knew those would be extremely high return on investment for a mill (and I was right about that worth every penny)2023年12月19日 But this limited cutting potential results in a lower removal rate for the vertical mill 7 Overarm and Arbor Support The horizontal milling machine has two elements not present in a vertical mill: an overarm and an arbor support The overarm is a Vertical Milling Machines vs Horizontal: Differences Explained2014年11月1日 The application of vertical mills in regrind circuits is consolidated This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when compared to Vertical mill simulation applied to iron ores ResearchGate2021年11月25日 The two dominating feed mixer types were the horizontal and vertical The horizontal feed mixers indicated mixing time of 1510 min, mixing speed of 4080 rpm, energy consumption per mix of 093 Construction and Evaluation of a Vertical Motorized Feed Mixer

Ball Mill Maintenance Installation Procedure

2016年10月20日 The mill gear should be lifted by the pinion causing a downward pressure on the pinion shaft bearing Mills are made either right or left “hand” There are two methods of identifying the “hand” of the mill When 2021年1月29日 Vertical roller mills, VRMs, are widely used for grinding raw materials in factories engaged in the extraction and processing of minerals Any machine used for grinding or crushing consumes around Increase productivity of vertical roller mill using seven The major design features of the tower mill are (1) a central agitator screw, the only moving machine component in contact with the slurry and steel media, and (2) the vertical grinding chamber which minimizes overgrinding of the product This arrangement reduces energy consumption in fine grinding of minerals by 25% to 50% when compared to traditional Vertical mills for fine grinding – FLS2014年10月20日 Rio Paracatu regrind circuit Santos Júnior et al (2011) presented some data on the Paracatu Vertical Mill circuit process, as well as its comparison to the plant's conventional ball millRegrind of metallic ores with vertical mills: An overview of the

.jpg)

(PDF) Design and Modify of Mill Discharge Valve Using in

2019年8月1日 Mill Discharge Valve (MDV) In open position the disc (flap) of the valves are always in vertical positions and are in the path of coal powder and air mixturesThe mill feed chute is retractable and rail mounted, particles are in red colour near the mill toe position Figure 4 – DEM Shell Liner modelling Visualisation VANCOUVER 2015 6 Figure 6 – General assembly of the 32ft Kansanshi SAG mill showing feed and discharge liners STEP CHANGE IN LINER DESIGN FOR THE KANSANSHI 32FT SAG MILL2022年5月31日 Mineral crushing is the main source of energy consumption in mineral processing According to statistics, this consumption accounts for about 35–50% of the total cost of the mine (Curry et al, 2014), or even higherIt may also account for 18% of the global electrical energy consumption (NapierMunn, 2015)More efficient crushing equipment needs to be Analysis of vertical roller mill performance with changes in G0796 9" x 49" 3 HP Vertical Mill with Power Feed and DRO Amazing features at an affordable price The G0796 9" x 49" Vertical Mill with power feed and DRO is a full featured mill built for those that only have singlephase power This machine has a 2axis DRO to ensure exact table position at all times With the 9" x 49" table, you can set up a rotary table or another fixture on Grizzly G0796 9" x 49" Vertical Mill with Power Feed and DRO

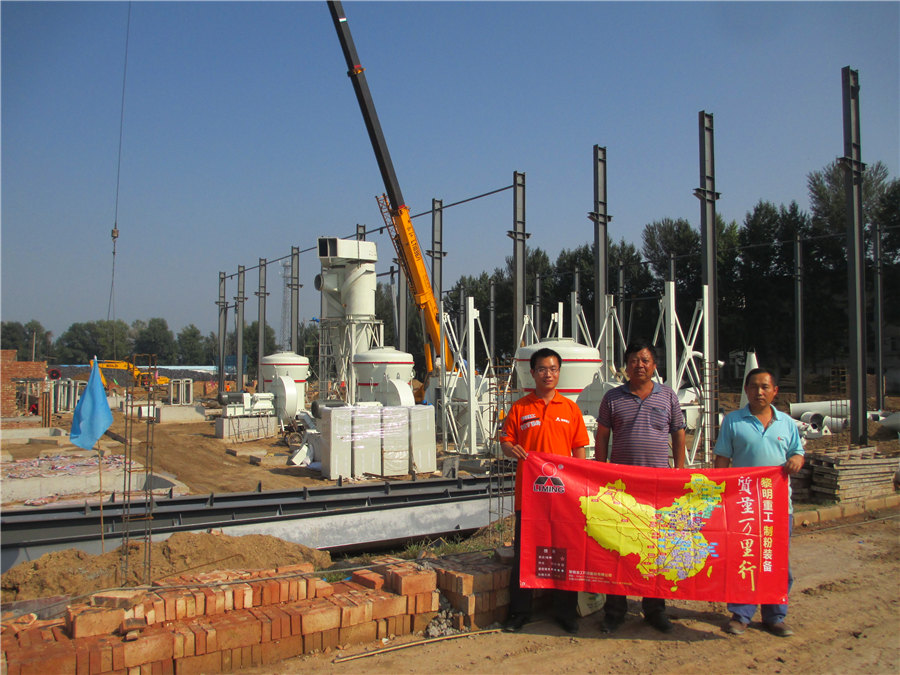

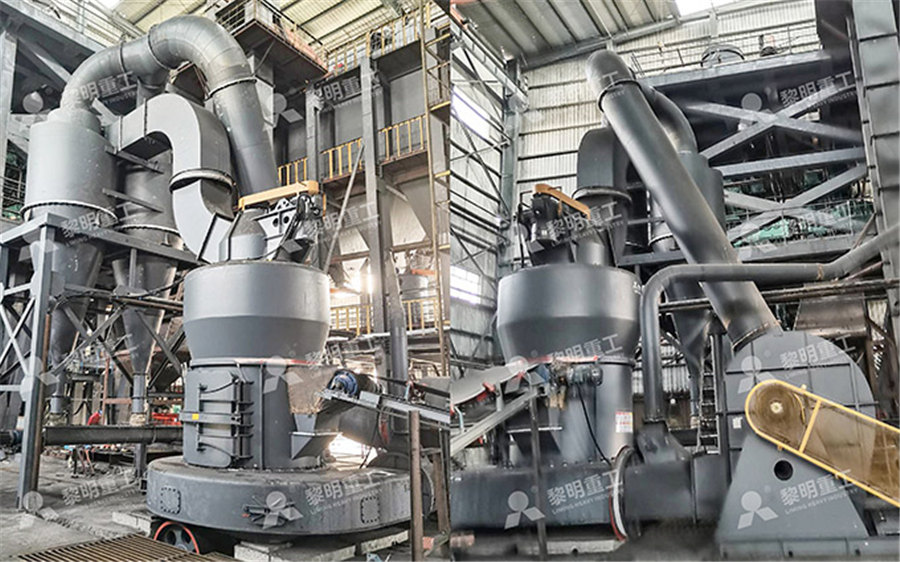

CFB石灰石脱硫剂制备——磨机公众号12.8 推送案例(8)51.jpg)

Coal mill, gypsum mill, clay mill, etc Pfeiffer MPS mills

MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, Feed size: up to 100 mm: Feed moisture: up to 35% (surface moisture) Target fineness degrees: 60 100 µm: Discharge of adverse ingredients as an option: 5: Maintenance door with LiftandSwing System: 6:2015年9月1日 Discharge of pebbles, finer rock, ball scats and slurry from mills and its flow through trommels, and into other processing operations has strong impacts on overflow ball mill performanceSimulation of overflow ball mill discharge and trommel flow using Download scientific diagram TowerMill Ò (Eirich courtesy) and Vertimill™ (Metso courtesy) from publication: Vertical Agitated Media Mill scaleup and simulation Vertical Agitated Media TowerMill Ò (Eirich courtesy) and Vertimill™ (Metso vertical positions and are in the path of coal powder and air mixtures So due to continuous The mill discharge valve is flap typethe flap is alwaysfrom the coal Design and Modify of Mill Discharge Valve Using in

Vertical Milling Machine Working Principle And

Vertical milling machines are crucial tools in the world of machining, contributing to the creation of various products we use daily Their importance lies in their unparalleled versatility and precision in the creation of intricate components Duplex Mill Mfg Co PO Box 1266, 415 Sigler St Springfield, OH 45501 USA PH: 937 Price list number: DN1003 PL MQW Ref: Q, Effective: 1/1/01 Comments: None Vertical Mixer Notes 1 Kelly Duplex Vertical Feed / Seed Mixers are suitable for mixing most free flowing materials A discharge must be selected from this section Duplex Mill Mfg Co Vertical Feed / Seed MixersStudy with Quizlet and memorize flashcards containing terms like What part of the vertical milling machine allows workpieces to be raised and lowered?, Briefly describe the direction of movement provided by the saddle, When a table handle is turned clockwise the table moves the operators position and moreMachine Processes Section 6 unit 1 Flashcards QuizletThe mill also has vertical arrangement VXP Mill is a product of FLSmidth company and is vertically oriented stirred media mill The mill is often used in flotation concentrate regrind and precious metals tailings retreatment where the feed size is typically 200 µm [11,12] HIG Mill is a recently developed technology by MetsoOutotech company(PDF) Performance Comparison of the Vertical and Horizontal

Review on vertical roller mill in cement industry its

2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage a vertical mill correctly takes more skill and experience than is required for lathe operation because of the additional axis (vertical) and the more varied type of work which can be performed For those wanting to learn more, we have written a 350page color book called Tabletop Machining (P/N 5301) that covers the subject in much greater detailVERTICAL MILLING MACHINE OPERATION VCSHobbiesof 80mm The raw materials are mixed in a certain proportion and fed into a vertical roller mill (LOESCHE mill) The vertical roller mill grinds the marital to D 85 of 90µm The ground product is calcined in a preheater to 850900℃ After calcination, the materials enter to a rotary kiln and heated to 1450℃ to become clinkerModeling and simulation of vertical roller mill using population feed pipe and wash pipe Scraper knife with vertical movement, feed and wash disk † Applicationspecific feed and wash systems: feed and wash pipe or inclined feed and wash disk † Position of filtrate discharge as well as cover opening can be chosen as required † Scraper unit systems: scraper knife over the entire basket height or scraperVertical scraper and top discharge centrifuges for chemical, fine

Performance Comparison of the Vertical and Horizontal Oriented

Minerals 2023, 13, 315 5 of 16 Figure 4 Pilot scale M20 and its internal structure (on the right) 22 Sampling of FullScale HIGMill and Pilot Tests of IsaMill2019年4月16日 Production capacity of the feed mill is defined based on continuous processes in tonnes per 300 secondsor five minutes per hour would be needed tofill and discharge the mixer 55 minuteswould be net mixing time Selecting optimal mixer options in feed milling2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics and HRM1700MVRM Free download as PDF File (pdf), Text File (txt) or read online for free The document provides installation and operation instructions for the HRM1700M Vertical Roller Coal Mill It describes the mill's technical parameters, components, structure, working principles, and installation process Key aspects include grinding rollers that can be removed for Operation Manual: HRM1700M Vertical Roller Coal Mill

PREDICTING THE PRODUCT PARTICLE SIZE DISTRIBUTION FROM A VERTICAL

Figure 37 Size analysis for a repeat experiment performed in a vertical mill shown as a function of grinding time for a single 595 +420μm feed size 71 Figure 38 Vertical mill geometry (left) and RockyDEM simulation of the vertical mill2017年2月13日 This should show the ball mill (feed, discharge and position of drive); Unit Flotation Cell or a Mineral Jig, if in circuit, and classifier Grinding Rods High carbon steel rods are recommended, hot rolled, hot sawed or sheared, to a length of 2″ less than actual length of mill taken inside the linersBall Mills 911Metallurgist2018年12月15日 Regular readers know I recently adopted a PM25MV vertical mill from Precision Matthews It has proven to be an excellent machine, and I recommend it highly to anyone I ordered it with the DRO and power feed options, because I knew those would be extremely high return on investment for a mill (and I was right about that worth every penny)Vertical Mill – Power Feed – Blondihacks2023年12月19日 But this limited cutting potential results in a lower removal rate for the vertical mill 7 Overarm and Arbor Support The horizontal milling machine has two elements not present in a vertical mill: an overarm and an arbor support The overarm is a Vertical Milling Machines vs Horizontal: Differences Explained

.jpg)

Vertical mill simulation applied to iron ores ResearchGate

2014年11月1日 The application of vertical mills in regrind circuits is consolidated This type of mill is now attracting interest in primary grinding applications, due to its higher efficiency when compared to 2021年11月25日 The two dominating feed mixer types were the horizontal and vertical The horizontal feed mixers indicated mixing time of 1510 min, mixing speed of 4080 rpm, energy consumption per mix of 093 Construction and Evaluation of a Vertical Motorized Feed Mixer