Limestone ore powder grinding production process

Limestone Powder Grinding Process ALPA Powder Equipment

2024年8月26日 There are two main processes for limestone grinding: Opencircuit process: the process in which the material passes through the mill once and is used as the finished product for the next stage of operation;2022年5月22日 Fine and ultrafine grinding of limestone are frequently used in the pharmaceutical, chemical, construction, food, and cosmetic industries, however, research EnergyModel and Life CycleModel for Grinding Processes of Process flow diagram for limestone processing operations Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Limestone Quarrying and Processing: A LifeCycle Inventory2024年2月23日 The production of limestone powder involves a series of carefully controlled steps to transform raw limestone into a versatile and valuable material Here's an overview of the typical limestone powder making process:Introduction of limestone powder making process and

1117 Lime Manufacturing US EPA

processes in the production of lime are: (1) quarrying raw limestone; (2) preparing limestone for the kilns by crushing and sizing; (3) calcining limestone; (4) processing the lime further by The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields Limestone Grinding Mill Plant TAYMACHINERYLimestone is a key raw material for producing cement, concrete aggregates, lime, calcium carbonate, and more Its crushing and grinding typically use dry processing, and the Limestone Grinding Process and Production CasesGrinding mills are indispensable in the process of creating limestone powder, serving as a key component in various industries Their primary function lies in transforming raw limestone into The Role of Grinding Mills in Limestone Powder Production

Grinding Limestone powder: A Comprehensive Guide

This paper mainly introduces the main uses of limestone powder, the production process and the selection of related grinding equipmentThe limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERYThe use of fossil fuels such as coal, natural gas, and oil is common in cement production, both as a fuel for the kiln and as a source of heat for other parts of the process which leads to CO2 emitted by combustionHowever chemical reactions happening in the kiln (calcination) are also responsible for up to 60% of the total of emissions of the cement production process [PCA]Cement Production Demystified: StepbyStep Process and The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

Limestone Ultrafine Grinding Mill

Limestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has stable operation, nonmetallic ores, with Mohs hardness less than 6 Such as marble, calcite, dolomite, Composition of limestone powder grinding mill production line The mill production line usually includes a hammer crusher, 2022年5月22日 Normalized and weighted values in the wet grinding process in nanograms (Functional unit: 1 kg of limestone product Impact assessment method: CML 2001/Aug 2016EnergyModel and Life CycleModel for Grinding Processes of Limestone 2021年12月28日 ④ Bucket elevator: The finely crushed limestone is lifted and sent to the limestone grinding mill, with strong lifting capacity, the low energy consumption of the motor, and long service life ⑤ Limestone grinding mill: It is the main equipment of the production line, and it is also the equipment that determines the quality of the finished powderHow to grind limestone into powder?2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine Powder

Types of Crushers: Choosing the Right One for Each Stage

2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers are widely used in ore crushing, aggregate production, 2023年10月6日 Ground calcium carbonate (GCC) production involves grinding and processing limestone or marble to obtain a range of particle sizes and characteristics suitable for various industrial applicationsGround Calcium Carbonate GCC Limestone powder grinding 11171 Process Description 15 Lime is the hightemperature product of the calcination of limestone Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains1117 Lime Manufacturing US EPAThe HGM Micro Powder Grinding Mill can meet different production requirements, with high grinding efficiency and a fineness of up to 5μm, it is the ideal mill for ultrafine powder processing 3 CLUM Series Ultrafine Vertical Roller MillGrinding Limestone powder: A Comprehensive Guide

How Lime is Made

To cook or “calcine” limestone, there must be a significant transfer of heat to the limestone In general, the heat transfer from the fuel source to limestone can be divided into two stages: Calcining – the kiln fuel is burned in the preheated air from the cooling zone and, as the limestone moves down the kiln, the heat turns the limestone into quicklime and carbon dioxide (CO 2 )2018年8月30日 Limestone powder is a byproduct of the limestone quarry, and it has been used in cementbased materials for many years In 1938, Bessey [6] first reported that CaCO 3 could react with cement to form calciumcarboaluminate The formation of calciumcarboaluminate was influenced by the amount and fineness of LS, but it had little effect on the compressive A review on use of limestone powder in cementbased materials How does the dolomite micro powder grinding mill work? Dolomite micro powder grinding mill is the equipment used to process ore such as dolomite (also known as limestone) into fine powder It converts raw dolomite ore into highquality dolomite fine powder through processes such as crushing, grinding and gradingDolomite Micro Powder Grinding Mill2024年1月29日 After grinding limestone into powder, it has various uses depending on the fineness of the powder and its chemical properties Here are some common uses: Manufacture of Building Materials: Limestone powder is often used in the production of cement The calcium oxide (CaO) in limestone plays a crucial role in cement manufacturingHow to choose limestone grinding mill? SANDMINE

.jpg)

How to choose a limestone grinding mill SANDMINE

2024年1月18日 Limestone powder production is generally divided into four types: coarse powder processing (03mm), fine powder processing (20 mesh400 mesh), ultrafine powder deep processing (400 mesh1250 mesh), and micro powder processing (1250 mesh3250 mesh) The limestone powder milling process mainly consists of the following stages:2024年7月12日 The grinding process requires precise control over fineness, typically requiring the powder to reach 200 mesh (74 μm) or finer Choose according to your production needs: the Raymond mill handles up to 22 t/h, the ultrafine mill up Pelletized Lime Production: A Detailed Howto Guide2021年4月19日 Grinding of finished cement is performed in a single stage, intergrinding materials with very different grindabilities This intergrinding process has many different interactions among the different components of the finished cement In a context of developing more sustainable and less energy intensive processes, it is important to understand the Resistance to Grinding and Cement Paste Performance of Blends 2020年3月12日 Limestone is the main raw material for the production of cement, concrete aggregate, lime, etc Crushing and grinding of limestone generally adopts the dry process, and the corresponding process Limestone grinding process

Production Process CEMEX Philippines

Clinker is the intermediate product used in the manufacturing of cement There are two primary processes used to manufacture clinker: the dry process and the wet process Our plants use the dry process, which is more energy efficient In the wet process, the raw materials are mixed with water to form slurry, which is fed into a kilnClirik HGM series limestone powder ultrafine grinding mill is used in the production line of a customer in India producing 5 tons of limestone powder per hour Our Limestone powder grinding mill can process all mining materials Limestone Powder Grinding Mill In India Clirik6 天之前 The manufacture of Portland cement is a complex process and done in the following steps: grinding the raw materials, mixing them in certain proportions depending upon their purity and composition, and burning them to sintering in Manufacturing of Portland Cement – Process and PDF On Jul 11, 2018, Sandra Lúcia de Moraes and others published Iron Ore Pelletizing Process: An Overview Find, read and cite all the research you need on ResearchGateIron Ore Pelletizing Process: An Overview

Limestone Ultrafine Mill Machine SBM Ultrafine Powder

2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ kinds of nonmetallic minerals with Mohs hardness less than 6, such as calcium carbonate, talc, calcite, carbon black, dolomite, mica, etcTo cater to specific material characteristics and meet customer requirements, SBM provides a range of grinding mills, including the MTM, MTW, LM, LUM, and SCM series Ecofriendly Production To ensure environmentally friendly production, various measures are implemented, including the adoption of dust removers and sealing at each componentlimestone grinding mill, limestone grinding machine, limestone The Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill2023年2月27日 Limestone is a sedimentary rock composed mostly of calcium carbonate It is used as a building material, a source of lime for the steel industry, and in the production of cementlimestone production process LinkedIn

-2.jpg)

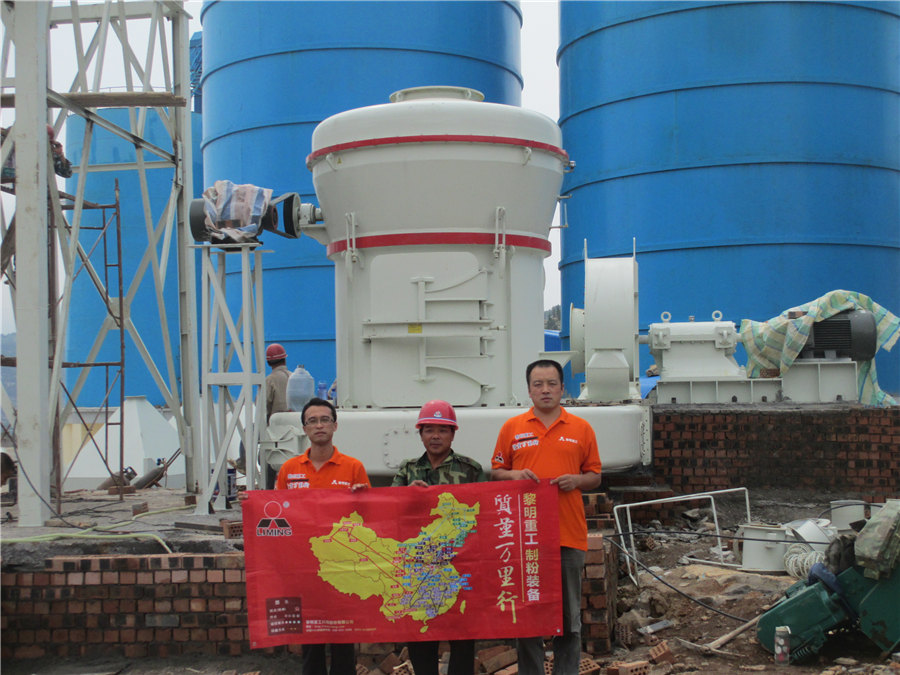

Limestone ultrafine grinding production line customer site

2023年12月6日 The production line mainly produces limestone powder of more than 800 mesh The customer said:”The operation is very stable, the grade of the finished product is quite high, and the actual output is much higher than the estimated production capacity, which helps us achieve better economic benefitsPROJECT REPORT ON LIME STONE POWDER (GRINDING) Free download as PDF File (pdf), Text File (txt) or read online for free Limestone is one of the most common minerals in the crust of the earth, and can be found all over the world as it covers about 10 % of the surface of the earth It is a relatively young mineral and therefore it can be found near the surfaceProject Report On Lime Stone Powder (Grinding) Scribd2024年9月10日 Steps of Cement Manufacturing The steps involved in cement manufacturing are as follows: Quarrying: Raw materials such as limestone and clay are extracted from quarries or mines; Crushing and Grinding: The extracted raw materials are crushed and ground into a fine powder; Blending: The crushed and ground raw materials are blended in specific proportions Cement Manufacturing Process: Know Extraction, Processing The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

Cement Production Demystified: StepbyStep Process and

The use of fossil fuels such as coal, natural gas, and oil is common in cement production, both as a fuel for the kiln and as a source of heat for other parts of the process which leads to CO2 emitted by combustionHowever chemical reactions happening in the kiln (calcination) are also responsible for up to 60% of the total of emissions of the cement production process [PCA]The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERYLimestone ultrafine grinding mill can process fine limestone powder, fineness: 1503000 mesh adjustable It has stable operation, nonmetallic ores, with Mohs hardness less than 6 Such as marble, calcite, dolomite, Composition of limestone powder grinding mill production line The mill production line usually includes a hammer crusher, Limestone Ultrafine Grinding Mill2022年5月22日 Normalized and weighted values in the wet grinding process in nanograms (Functional unit: 1 kg of limestone product Impact assessment method: CML 2001/Aug 2016EnergyModel and Life CycleModel for Grinding Processes of Limestone

.jpg)

How to grind limestone into powder?

2021年12月28日 ④ Bucket elevator: The finely crushed limestone is lifted and sent to the limestone grinding mill, with strong lifting capacity, the low energy consumption of the motor, and long service life ⑤ Limestone grinding mill: It is the main equipment of the production line, and it is also the equipment that determines the quality of the finished powder2023年12月8日 Limestone Properties The main component of limestone is calcium carbonate (CaCO3), with a Mohs hardness of 3 After limestone is mined from limestone, it is crushed to form limestone particles, that is, stone and sand, or further ground to form limestone powder, which is widely used in industries such as building materials, highways, metallurgy, and Limestone crushing technology and equipment SBM Ultrafine Powder 2024年7月17日 A crusher, also known as a stone crusher, is a machine that uses mechanical action to break large rocks, ores, or other raw materials into gravel or rock powder Crushers are widely used in ore crushing, aggregate production, Types of Crushers: Choosing the Right One for Each Stage2023年10月6日 Ground calcium carbonate (GCC) production involves grinding and processing limestone or marble to obtain a range of particle sizes and characteristics suitable for various industrial applicationsGround Calcium Carbonate GCC Limestone powder grinding

.jpg)

1117 Lime Manufacturing US EPA

11171 Process Description 15 Lime is the hightemperature product of the calcination of limestone Although limestone deposits are found in every state, only a small portion is pure enough for industrial lime manufacturing To be classified as limestone, the rock must contain at least 50 percent calcium carbonate When the rock contains