Efficient and energysaving limestone calcium carbonate mill

.jpg)

New Insight into EnergySaving Calcination of

2023年11月2日 This study presents an energysaving calcination strategy using low temperatures and a controlled heating process for preparing partially calcined limestone The low temperature and controlled heating ensure the high activity 2023年11月2日 In this study, the limestone is partially calcined to form the core–shell structure with loose calcium oxide on the outside and dense calcium carbonate on the inside, and New Insight into EnergySaving Calcination of Limestone: 2022年8月20日 Steam accelerates the reaction rate and reduces the calcination temperature by ∼100 °C Adding steam reduces the energy requirement, thus reducing the CO 2 footprint of The steamassisted calcination of limestone and dolomite for energy 2018年8月15日 Shear and impact based drymillings promote sintering of the nascent CaO after calcination, which hinders CO 2 capture In contrast, highly energetic drymilling combining Effect of milling mechanism on the CO2 capture performance of limestone

.jpg)

New Insight into EnergySaving Calcination of Limestone

2023年11月2日 This study presents an energysaving calcination strategy using low temperatures and a controlled heating process for preparing partially calcined limestone The 2018年4月19日 Results from process simulations show that the highest efficiencies for the CaLCSP integration are achieved at carbonator absolute pressures of ∼35–4 bar, which leads to an overall plant efficiency (net electric Carbonation of Limestone Derived CaO for Limestone and dolomite, after being pretreated thermally at high temperatures (1000 or 1100 °C), showed a substantial increase in calcium utilization over many calcination/carbonation cycles LongTerm Calcination/Carbonation Cycling and Thermal Pretreatment 2023年6月12日 The indirectly heated carbonate looping (IHCaL) process is an efficient candidate for this application because it utilizes lime as the sorbent for the CO2 capture In this Negative CO2 emissions in the lime production using an

.jpg)

Efficient CO2 capture from lime plants: Technoeconomic

2024年6月1日 Technoeconomic assessment on ten CO 2 capture configurations for lime production IHCaL technology is promising in terms of economic viability and energy efficiency 2023年12月11日 It is helpful to have a chemical reaction kinetics understanding of the lime calcination process in order to identify energy efficiency improvement options for the lime kiln IMPROVING THE ENERGY EFFICIENCY OF A LIMESTONE 2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the Guide to Calcium Carbonate Grinding: Mills, 2024年10月14日 b low energy consumption cternal system optimization and higher efficiency d intelligentize system eimprovements in enviromental protection Application Suitable for processing of nonmetallic minerals such as calcium carbonate,clay,barite,talc,gypsum,limestone,calcium oxide,bentonite,dolomite etc Detail Calcium Carbonate Powder Mill for Limestone, Calcite,

CALCIUM CARBONATE (GCC) Hosokawa

2020年5月13日 CALCIUM CARBONATE (GCC) REDUCING OPERATING COSTS THROUGH from chalk, limestone or marble is challenging today GCC stands for dry powder or a suspension and is indispensable in today's industry an energyefficient The ATR agitator ball mill is used for the ultrafine grinding of preground mineralSBM high quality calcium carbonate ultrafine powder vertical mill is widely used in many fields +17 which can greatly improve the working efficiency of the mill and improve the whiteness and cleanliness of the finished product 2 More energysaving multihead powder selection technologyCalcium Carbonate Ultrafine Powder Vertical Mill2023年9月28日 The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specifications Energy Efficiency: Vertical mills are known for their energyefficient operation calcium carbonate ball mill is a type of Exploring Different Grinding Mills for Calcium Carbonate In a bid to enhance their production capabilities and expand their product offerings, this customer has invested in 3 sets of HGM125 micro powder grinding millsThese mills are specifically used to produce ultrafine calcium carbonate and coal powder, achieving a fineness of 600 meshThe final product, which expands upon mixing with water, is utilized as an expansion agent in various Calcium Carbonate and Coal Powder Production Line In China

制粉项目-2023.11.17.jpg)

How to Choose a Calcium Carbonate Grinding Mill DASWELL

2024年9月13日 The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder Choose a suitable one! It has the characteristics of large output, high efficiency, low energy consumption and environmental protection 3Energy saving; 4High yield Micro powder roller mill 545Grinding Ring: The grinding ring is the main component that provides the necessary compression and shearing force for grindingIt rotates and provides the surface against which the rollers press the material Grinding Rollers: These are cylindrical rollers that apply the grinding pressure to the material against the grinding ringThey roll on the ring and crush the material into fine particlesRing Mill For Ultrafine Grinding Calcium Carbonate2003年3月13日 The calcination of limestone to produce lime and cement is characterized by its highenergy consumption and concomitant CO2 emissions to the atmosphere By combining the calcination reaction with the partial oxidation and CO2reforming of methane, an overall thermoneutral process can be designed, with highquality syngas as a useful byproduct, and a Thermoneutral Coproduction of Calcium Oxide and Syngas High grinding efficiency:High grinding efficiency and low energy consumption, saving 40% 50% power consumption compared to ball millSpecial structure design of grinding roller and grinding table, large diameter of grinding roller, large grinding area, hydraulic automatic pressure deviceLUM series superfine vertical roller grinding mill

Dolomite Grinding Mill SBM Ultrafine Powder

2021年7月28日 Dolomite grinding mill is a highly efficient industrial grinding mill, it can grind dolomite into a fine powder(1503000 mesh) glass and refractory materials, chemical industry, agriculture, environmental protection, energy The ring and roller are forged by special material with high utilization Under the same grinding material and finish special size, the lifecycle of spare parts is about one year, which is 23 times longer than an impact mill or turbo mill Ultra Fine Grinding Mill SBM Ultrafine Powder MTW European Type Trapezium Mill is the upgrade product of Traditional Raymond mill and Pendulum Mil heavy calcium carbonate processing, nonmetallic mineral powder making, solid fuel grinding, building materials and MTW European Type Trapezium Mill, raymond Grinding Mill, Raymond Mill, Ball Mill manufacturer / supplier in China, offering Big Capacity Stone Quarry Plant Used Calcium Carbonate Gypsum Limestone Quartz Graphite Calcite Feldspar Fluorite Impact Crusher, Hot Sale Dolomite Pyrophyllite Mineral Phosphorite Marble Perlite Sepiolite Silica Powder Jaw Crusher Price with High Efficient Capacity, Low Cost Calcite Raymond mill; Superfine grinding mill; Vertical roller mill

.jpg)

Efficient Grinding Of Calcium Carbonate Calcium Oxide:

2024年11月1日 Good grinding effect: Calcium carbonate and calcium oxide processed by HGM125 mill have uniform fineness and reasonable particle size distribution, which can be widely used in many industries such as coatings, plastics, rubber and building materialsHGM Ultra fine powder mill is a high efficient device to break hard stone into micro powder, such as calcium carbonate, mica, limestone, etc +17 [ protected]Ultra Fine Powder MillCalcium Carbonate (GCC) produced from chalk, limestone, calcite or marble have developed in recent years from just being a simple cheap filler to highest quality functional additives The vertical agitated media mill ANR is employed for the energyefficient ultrafine grinding of highly concentrated limestone slurries (GCC) The most typical Calcium Carbonate (GCC) Hosokawa AlpineMTM Trapezium Mill is designed for pulverizing minerals, such as quartz, feldspar, calcite, talcum, barite, fluorite, marble, ceramic, bauxite, iron ore, copper ore, etc MTM adopts highly efficient and energysaving impeller fan It is much more efficient than straight blade fan Limestone Mill Kaolin Processing Calcium Carbonate PlantMTM Series Medium Speed Trapezium Mill zenithmills

.jpg)

Production of precipitated calcium carbonate from calcium silicates

2005年11月1日 The possibilities for reducing carbon dioxide emissions from the pulp and paper industry by calcium carbonation are presented The current precipitated calcium carbonate (PCC) production uses 2023年5月11日 22 ABSTRACT 23 Limestone powder (LP) and sodium metaaluminate (SMA) were used to fabricate calcium 24 carbonatebased cementitious material, as a solution to address the solid waste problem The effects 25 of SMA doses and curing conditions on the hydration properties and mechanical performance of paste 26 were investigated The results Fabrication of energyefficient carbonatebased 2024年5月13日 High Efficiency: Raymond mill has a high grinding efficiency that can reach up to 99% for calcium carbonate Energy Saving: The use of advanced pulse dust collector reduces energy consumption Commonly Used Calcium Carbonate Grinding Mill raymond mill Calcium carbonate stones need to be treated by jaw crusher and hammer crusher, so that its particle size is reduced to 1020 mm, in order to adapt to the feed requirements of the mill Grinding The crushed small pieces of CaCO3 are lifted to the silo by a bucket elevator, which is then uniformly and quantitatively transported by a vibrating Calcium Carbonate: Grinding and Applications Overview Grinding Mill

.jpg)

EnergyEfficient Advanced Ultrafine Grinding of

2023年7月10日 The present literature review explores the energyefficient ultrafine grinding of particles using stirred mills The review provides an overview of the different techniques for size reduction and the impact of energy The limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder Fineness2021年7月20日 CLIRIK HGM series ring roller mill for calcium carbonate powder making CLIRIK HGM series ring roller mill (characterized by large pulverization ratio and low energy consumption per unit product): The ring roller mill mainly performs ultrafine processing of heavy calcium, and mainly produces 2002500 purpose productsCalcium carbonate grinding millCLIRIK Machinery2023年9月19日 Heavy calcium carbonate (heavy calcium) is made by directly crushing natural limestone, calcite, etc, by mechanical methods (Raymond mill or ultrafine vertical Grinding mill and other grinding equipment) The output is more than double that of a ball mill, while the energy consumption of the system is only 30% of that of an airflow mill 2 Calcium carbonate milling process SBM Ultrafine Powder

Limestone Powder Grinding Mill Machinery

2020年12月3日 Benefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the 2024年6月7日 EPIC Powder's ring roller mill is ideal for producing ultrafine calcium carbonate powder with low investment and high efficiency One of the advantages of the ring roller mill is its high grinding efficiency The grinding ring and rollers are made of highquality materials, which ensures a long service life and reduces maintenance costs Ring Roller Mill Ultrafine calcium carbonate production It is an energysaving high fine powder processing equipment It can be used for ultrafine grinding mill of various nonmetallic minerals such as limestone, talc, calcite, calcium carbonate, dolomite, potassium feldspar, bentonite, kaolin, fluorite, etc with Mohs hardness below 7 and humidity within 6%HCH Ultrafine Grinding Mill, Micro powder grinding mill, These systems improve efficiency, reduce energy consumption, and enhance the quality of the clinker Word count: 1500 Energy Efficiency and Optimization Improving energy efficiency is a key focus for cement kiln operators, as it reduces fuel consumption and lowers operating costs Techniques to Improve Energy EfficiencyComprehensive Guide to Cement Kilns: Processes, Types, Efficiency

Guide to Calcium Carbonate Grinding: Mills,

2023年6月25日 Crushing: The calcium carbonate stones just mined from the quarry are relatively large, and they need to be crushed by a jaw crusher and a hammer crusher in turn to the feed fineness (10mm20mm) that can enter the 2024年10月14日 b low energy consumption cternal system optimization and higher efficiency d intelligentize system eimprovements in enviromental protection Application Suitable for processing of nonmetallic minerals such as calcium carbonate,clay,barite,talc,gypsum,limestone,calcium oxide,bentonite,dolomite etc Detail Calcium Carbonate Powder Mill for Limestone, Calcite, 2020年5月13日 CALCIUM CARBONATE (GCC) REDUCING OPERATING COSTS THROUGH from chalk, limestone or marble is challenging today GCC stands for dry powder or a suspension and is indispensable in today's industry an energyefficient The ATR agitator ball mill is used for the ultrafine grinding of preground mineralCALCIUM CARBONATE (GCC) HosokawaSBM high quality calcium carbonate ultrafine powder vertical mill is widely used in many fields +17 which can greatly improve the working efficiency of the mill and improve the whiteness and cleanliness of the finished product 2 More energysaving multihead powder selection technologyCalcium Carbonate Ultrafine Powder Vertical Mill

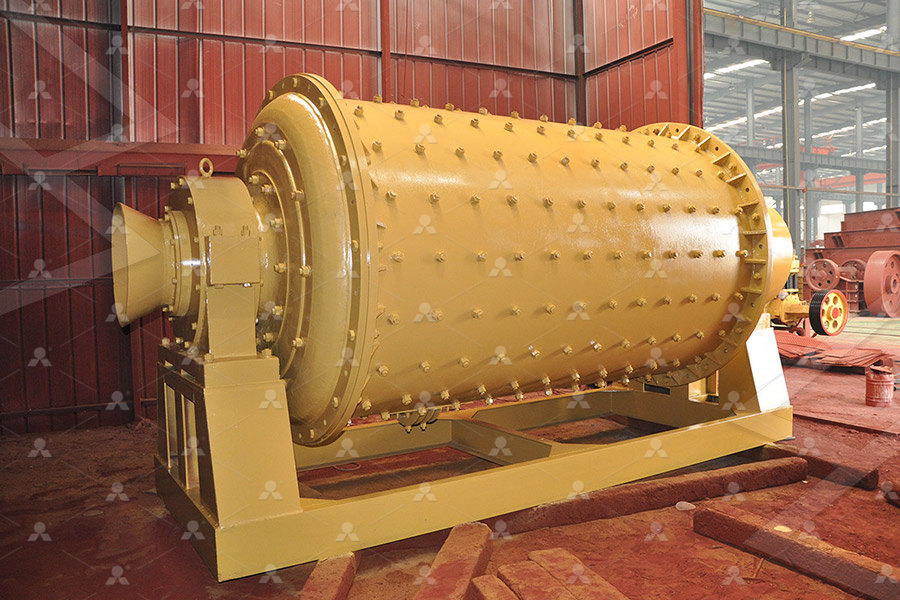

Exploring Different Grinding Mills for Calcium Carbonate

2023年9月28日 The specific processes and equipment used in a calcium carbonate processing plant may vary depending on the source of calcium carbonate (such as limestone or marble) and the desired end product specifications Energy Efficiency: Vertical mills are known for their energyefficient operation calcium carbonate ball mill is a type of In a bid to enhance their production capabilities and expand their product offerings, this customer has invested in 3 sets of HGM125 micro powder grinding millsThese mills are specifically used to produce ultrafine calcium carbonate and coal powder, achieving a fineness of 600 meshThe final product, which expands upon mixing with water, is utilized as an expansion agent in various Calcium Carbonate and Coal Powder Production Line In China2024年9月13日 The selection of calcium carbonate grinding mill will affect the quality of the final ground calcium carbonate powder Choose a suitable one! It has the characteristics of large output, high efficiency, low energy consumption and environmental protection 3Energy saving; 4High yield Micro powder roller mill 545How to Choose a Calcium Carbonate Grinding Mill DASWELLGrinding Ring: The grinding ring is the main component that provides the necessary compression and shearing force for grindingIt rotates and provides the surface against which the rollers press the material Grinding Rollers: These are cylindrical rollers that apply the grinding pressure to the material against the grinding ringThey roll on the ring and crush the material into fine particlesRing Mill For Ultrafine Grinding Calcium Carbonate

Thermoneutral Coproduction of Calcium Oxide and Syngas

2003年3月13日 The calcination of limestone to produce lime and cement is characterized by its highenergy consumption and concomitant CO2 emissions to the atmosphere By combining the calcination reaction with the partial oxidation and CO2reforming of methane, an overall thermoneutral process can be designed, with highquality syngas as a useful byproduct, and a High grinding efficiency:High grinding efficiency and low energy consumption, saving 40% 50% power consumption compared to ball millSpecial structure design of grinding roller and grinding table, large diameter of grinding roller, large grinding area, hydraulic automatic pressure deviceLUM series superfine vertical roller grinding mill