Limestone production line equipment cooling

Lime production line mining processing machine XKJ Group

Pushed into the rotary kiln by hydraulic push rods, the limestone is calcined and decomposed into CaO and carbon dioxide in the rotary kiln The limestone generated after decomposition enters XKJ Group production line Mineral Calcination / Cooling Line equipment column provides you with the advantages, parameters, quotes, picture information of each Limestone rotary kiln Limestone rotary kiln production line mining processing We, Jiangsu Pengfei Group Co, Ltd supply complete equipments for active lime production line with capacity below 1200 ton per day The active lime is widely used in steel production, 600 tons of active lime production line equipmentJiangsu Pengfei Group Co, Ltd has the great comprehensive ability to provide the best quality services on turnkey basis with the complete equipment、 the installation and the debugging for the new type dry process rotary kiln cement factories under the daily capacity of 8000ton、5000ton and 2500ton and compound fertilizer plants under the annual capacities of the active lime production line equipmentChina Pengfei Group

Limestone Fertilizer Production Line

The limestone fertilizer production line is to make limestone granules or calcium carbonate granules It typically consists of several stages, including milling, screening, mixing, granulating, drying, and cooling The limestone fertilizer is 2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw 6 Cement Equipment For Dryprocess Cement The limestone fertilizer production line is to make limestone granules or calcium carbonate granules It typically consists of several stages, including milling, screening, mixing, granulating, drying, and cooling The limestone fertilizer is commonly used to adjust the pH level of soil and provide plants with a source of calcium Working ProcessLimestone Fertilizer Production Line Fertilizer Manufacturing Cement production line is a production line construction project composed of a series of supporting equipment for cement production It is mainly composed of crushing equipment, homogenizing equipment, raw meal preparation equipment, drying equipment, preheating and decomposition equipment, clinker burning equipment, cooling equipment, grinding equipment, Cement production lineNanjing BOSIHAN International Trade

600 tons of active lime production line equipment

Vertical preheater Vertical preheater is one of the main active lime equipment, the main effect of vertical preheater is the limestone material sent to the preheater, and use high temperature exhaust gas from the kiln calcining out emissions(1150 degrees Celsius), the material in the preheater evenly heated to about 900 degrees CelsiusIn the preheating process of Vertical preheater: Vertical preheater is one of the main active lime equipment, the main effect of vertical preheater is the limestone material sent to the preheater, and use high temperature exhaust gas from the kiln calcining out emissions(1150 degrees Celsius), the material in the preheater evenly heated to about 900 degrees CelsiusIn the preheating process of 600 tons of active lime production line equipmentThe cement production line is composed of a great variety of equipment, including rotary kiln, sintering furnace, ball mill, cement mill, dryer, granulating machine, crushing machine, dust collector, plate feeder, humidifying tower, bucket elevator, screw conveyor, as well as many other types of machines for material crushing, conveying, stacking and taking, weighting, heating, Cement Production Line Cement Plant Equipment RIGHT2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kilnLime Production Process and Required Equipment

Cement Production Line,Cement Machine,Rotary Kiln,Cement Equipment

2500TPD new type dry process cement clinker production line The 2500t / d cement clinker production line adopts a new dry process, with an annual output of 775,000 tons of cement clinker and a total cement output of 105 million tons / year A cement production line and auxiliary facilities from limestone crushing to cement packaging are The limestone crushing production line mainly consists of a vibrating feeder, jaw crusher, impact crusher, vibrating screen, belt conveyor, Home » News » Limestone Crushing Equipment and Production Line Contact Now +86 Limestone Crushing Equipment and Production LineLimestone is a sedimentary rock composed primarily of calcium carbonate with the occasional presence of magnesium Most limestone is biochemical in origin meaning the calcium carbonate in the stone originated from shelled oceanic creatures Limestone can also be chemical in origin as is the case with travertineLimestone Quarrying and Processing: A LifeCycle InventoryThe latest limestoneprocessing equipment is present at Kilkenny Limestone, from fast texturing options to a semiautomated tile cutting line Our advanced ITsystem allows for full traceability throughout the quarry and factory production process, which means each customerorder can be traced back to a certain layer in each quarry EquipmentKilkenny Limestone® production process Brachot

Clinker Production Clinker Manufacturing Cement

Step 3: clinker cooling Clinker cooling is the final step in clinker production This process aims to recycle heat, preheat the secondary air, and improve the quality and grindability of the clinker Besides, the rapid cooling of the clinker in this process is convenient for cement storage and transportation Clinker CoolerVerticle Shaft Kiln Introduction In factory of lime calcination, where precision and efficiency are paramount, vertical shaft kilns (VSKs) stand as stalwart contributors to the chemical transformation of limestone into quicklime As an engineer navigating the intricacies of industrial processes, understanding the design, components, and operational aspects of VSKs becomes Vertical Shaft Kilns in Optimizing Lime CalcinationThus, you need to determine how large a limestone fertilizer production line you want to build, and then you can equip your production line with the appropriate equipment 【Process flow】 A complete limestone fertilizer production line includes a multistep process flow such as raw material preparation, crushing, mixing, granulation, drying and cooling, and packagingLimestone Fertilizer Production SolutionsThe limestone fertilizer production line is to make limestone granules or calcium carbonate granules It typically consists of several stages, including milling, screening, mixing, granulating, drying, and cooling The limestone fertilizer is commonly used to adjust the pH level of soil and provide plants with a source of calcium Working ProcessLimestone Fertilizer Production Line bio pellet fertilizer

Price of Hot Selling Limestone Pellets Production Line

2023年9月25日 Limestone granulation plant as a mineral production line in SX is popular from the past data of customer For this, price is an item that customers always pay attention to However, the prices of limestone production lines with different outputs are different Hence, SX specially designed limestone pellets production lines with different outputs toThe limestone fertilizer production line is to make limestone granules or calcium carbonate granules It typically consists of several stages, including milling, screening, mixing, granulating, drying, and cooling The limestone fertilizer is commonly used to adjust the pH level of soil and provide plants with a source of calcium Working ProcessLimestone Fertilizer Production Line Fertilizer making machine CHAENG can undertake the 2001500t/d active lime production line EPC, including the the reach report, civil engineering, designing, equipment, installation and debugging +79; Production Line Limestone Grinding Line Materials: Calcium carbonate, limestone, barite, heavy calcium carbonate, active lime production line CHAENGUsing Rotary Kilns in Lime Production Rotary kilns account for 90% of lime production in the United States A rotary kiln consists of a long, cylindrical, slightly inclined, refractorylined furnace The limestone and combustion gases pass through the kiln in a countercurrent flow As the limestone moves down the kiln, the limestonePROCESSING • CHARACTERISTICS • PRODUCTION • KILNS • SOLUTIONS

Limestone crushing production line NEWS SMMVIK Machinery

Limestone crushing production line is a type of production line used to process limestone into crushed stone and sand industries When choosing a limestone crushing production line, factors such as the type, scale, and performance of the equipment, as well as the quality requirements of the final product, should be considered Previous: So far as India, the secondlargest producer of cement, is concerned, the mineral production statistics of the Indian Bureau of Mines (7), the apex body dealing with mines and minerals in the country, showed that the production of limestone Basics of mineral resources for cement production2022年4月20日 After limestone is mined from limestone rock, Limestone crushing and grinding production line 20/04/2022 admin Limestone Properties Introduction of limestone crushing equipment Primary Crusher – Jaw Crusher Basic information of equipment: 1 Limestone crushing and grinding production line SBM Ultrafine The limestone grinding production line is a production process for the fine processing of limestone raw materials The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of different fields This production line covers the complete process from raw material processing Limestone Grinding Mill Plant TAYMACHINERY

Cement Manufacturing Process INFINITY FOR CEMENT EQUIPMENT

Among the major raw materials required for cement production, limestone, sandstone, is accounted as one of the most main key factors which control the whole production line and specially the thermochemical process Kiln shell cooling equipment; Principles to be followed for closedown areLimestone Pellets Granulating Production Line Are you finding solutions to limestone disposal? Do you So you also need to use drying machine and cooling equipment In this way, the price of a whole set of 1030 t/h rotary drum limestone pellets production line about $200,000 – Limestone Pellets Granulating Production Line2024年1月23日 Limestone is a common sedimentary rock, primarily composed of calcium carbonate It is widely distributed in different regions of the Earth, forming extensive rock layers The color of limestone can vary due to impurities, including white, gray, yellow,hellip;Limestone crushing and screening production line introductionRotary Lime Kiln Kiln Body Length: 40 – 72 m Production Capacity: 200 – 1,200 t/d Calcination Temperature: 1100±50℃ Application: Active lime production, quick lime productionRotary Lime Kiln Rotary Kiln Lime Production AGICO CEMENT

.jpg)

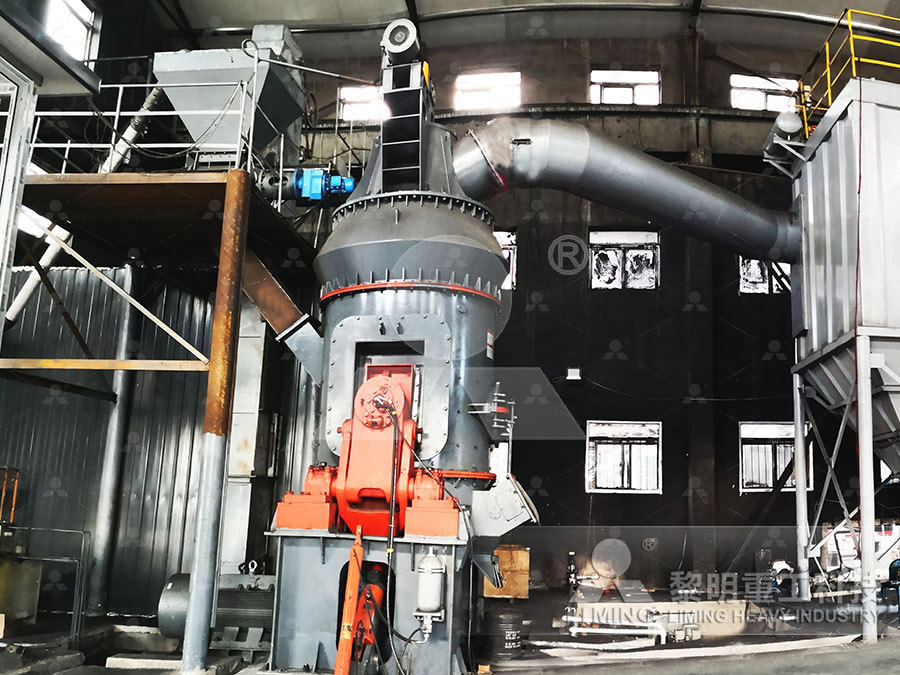

Limestone ultrafine grinding production line customer site

2023年12月6日 Recently, the HGM100 ultrafine mill production line of a customer in Binzhou, Shandong, China has been installed and officially put into production The production line mainly produces limestone powder of more than 800 mesh The customer said:”The operation is very stable, the grade of the finished product is quite high, and the actual Jiangsu Pengfei Group Co, Ltd has the great comprehensive ability to provide the best quality services on turnkey basis with the complete equipment、 the installation and the debugging for the new type dry process rotary kiln cement factories under the daily capacity of 8000ton、5000ton and 2500ton and compound fertilizer plants under the annual capacities of the active lime production line equipmentChina Pengfei Group The limestone fertilizer production line is to make limestone granules or calcium carbonate granules It typically consists of several stages, including milling, screening, mixing, granulating, drying, and cooling The limestone fertilizer is Limestone Fertilizer Production Line2023年12月26日 As we all know, the dryprocess cement production line is commonly used in the cement industry The new type of dryprocess cement production process includes four main sections: Prehomogenization of raw 6 Cement Equipment For Dryprocess Cement

Limestone Fertilizer Production Line Fertilizer Manufacturing

The limestone fertilizer production line is to make limestone granules or calcium carbonate granules It typically consists of several stages, including milling, screening, mixing, granulating, drying, and cooling The limestone fertilizer is commonly used to adjust the pH level of soil and provide plants with a source of calcium Working ProcessCement production line is a production line construction project composed of a series of supporting equipment for cement production It is mainly composed of crushing equipment, homogenizing equipment, raw meal preparation equipment, drying equipment, preheating and decomposition equipment, clinker burning equipment, cooling equipment, grinding equipment, Cement production lineNanjing BOSIHAN International Trade Vertical preheater Vertical preheater is one of the main active lime equipment, the main effect of vertical preheater is the limestone material sent to the preheater, and use high temperature exhaust gas from the kiln calcining out emissions(1150 degrees Celsius), the material in the preheater evenly heated to about 900 degrees CelsiusIn the preheating process of 600 tons of active lime production line equipmentVertical preheater: Vertical preheater is one of the main active lime equipment, the main effect of vertical preheater is the limestone material sent to the preheater, and use high temperature exhaust gas from the kiln calcining out emissions(1150 degrees Celsius), the material in the preheater evenly heated to about 900 degrees CelsiusIn the preheating process of 600 tons of active lime production line equipment

G[R.jpg)

Cement Production Line Cement Plant Equipment RIGHT

The cement production line is composed of a great variety of equipment, including rotary kiln, sintering furnace, ball mill, cement mill, dryer, granulating machine, crushing machine, dust collector, plate feeder, humidifying tower, bucket elevator, screw conveyor, as well as many other types of machines for material crushing, conveying, stacking and taking, weighting, heating, 2023年2月15日 The industrial production line of lime The whole lime production line includes: mining, crushing, screening and calcinating Mining highquality limestone First, limestone is quarried from mines with the help of big machines and blasting In this stage, limestone with big blocks which are not suitable for putting in a kilnLime Production Process and Required Equipment2500TPD new type dry process cement clinker production line The 2500t / d cement clinker production line adopts a new dry process, with an annual output of 775,000 tons of cement clinker and a total cement output of 105 million tons / year A cement production line and auxiliary facilities from limestone crushing to cement packaging are Cement Production Line,Cement Machine,Rotary Kiln,Cement Equipment