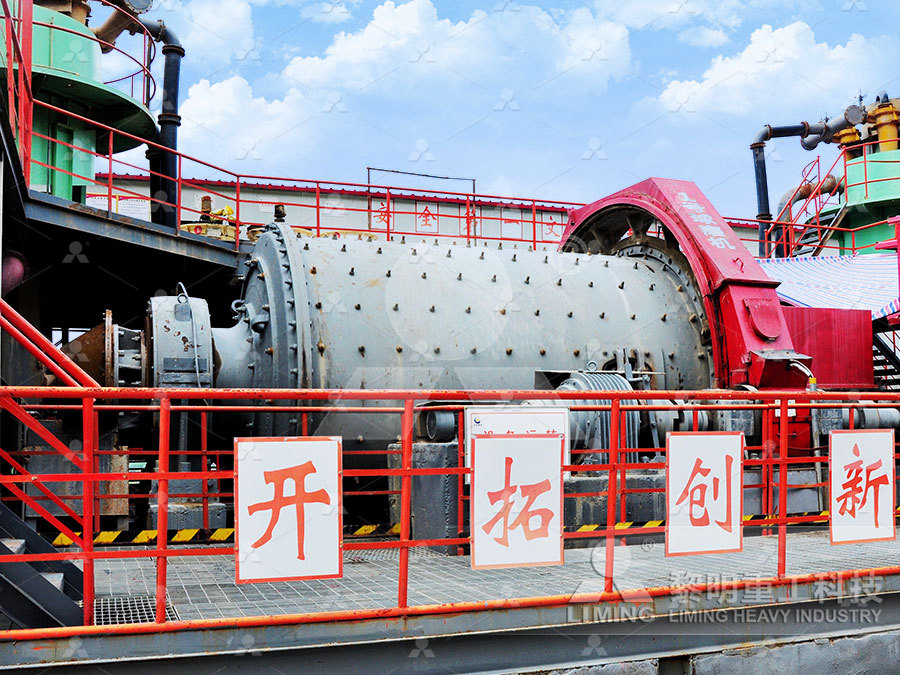

Nickel slag ore grinding machine

.jpg)

Nickel Slag Recycling Plant Nickel Slag Separator Jig Machine Nickel

2024年10月16日 Nickel slag is the solid waste residue produced by the smelting of nickeliron alloy Nickeliron alloy is mainly used for stainless steel production, so nickel slag is also called 2023年12月22日 Nickel Slag Grinders, Mills, Crushing Equipment, Grinding Machinery, Find Details and Price about Machine Milling Machine from Nickel Slag Grinders, Mills, Crushing Nickel Slag Grinders, Mills, Crushing Equipment, Grinding 2024年11月1日 Nickel laterite ore smelting slag is a byproduct of the ferronickel alloy production process Due to the low nickel content in the ore, a substantial amount of slag is generated Review on comprehensive utilization of nickel laterite ore2024年10月25日 Powder grinding mill 1500x4500 1830x7000 Nickel Slag Potash Ball Mill Product Description Grinding ball mill 1830x4500 is a kind of grinding equipment used in Powder Grinding Mill 1500X4500 1830X7000 Nickel Slag

.jpg)

Nickel Slag Ball Mill, Grinder, Grinding Machine, Grinding

2024年10月29日 Nickel Slag Ball Mill, Grinder, Grinding Machine, Grinding Machinery US$29,0000060,00000 / Piece: 1 Piece (MOQ)2024年4月15日 Here in this study, we proposed new artificially prepared slag systems with the optimized composition and thereof structure and that are suitable for nickel smelting processes Artificial Slags with Modulated Properties for Controlled Nickel Nickel production from highmagnesium nickel oxide ores follows a pyrometallurgical process including prereduction, smelting in a blast furnace, and nickel enrichment refining 71 During Nickel Slag an overview ScienceDirect Topics2022年2月11日 Keeping in view of the widespread data on resources of nickel and status of different technologies for nickel extraction, this article presents a brief overview about nickel Comprehensive Review on Metallurgical Upgradation Processes of Nickel

Review on hydrometallurgical processing technology of

2024年7月2日 Caron technology is a comprehensive technology for processing lateritic nickel ores, including pyro and hydrometallurgical processes Laterite ores are mainly processed 2023年11月8日 This study aims at recovering valuable metals from nickel slag by employing pyrometallurgical techniques A large amount of slag is generated during the nickel matte A Crucial Step Toward Carbon Neutrality in Pyrometallurgical 2023年10月1日 The nickel converter slag was provided by Kalgoorlie nickel smelter and collected from a historic pile The slag was prepared by a combination of jaw crushing, cone crushing and rod milling, followed by pulverised and sieved to produce a sample that passed 75 μm All the samples used in this study were under 75 µm unless plexation leaching of critical and strategic metals from nickel 2019年2月10日 Large volume of metallurgical slag is generated in nickel smelting process as a result of using laterite nickel ore with low content of nickel []It is estimated that production of 1 ton nickel–iron can produce 7–10 tons slag, which large size of land and causes serious environmental pollution []However, the laterite nickel slag still contains valuable metals in the Effect of Ultrasound on the Extraction of Silicon and

.jpg)

China Nickel Slag, Nickel Slag Wholesale, Manufacturers,

China Nickel Slag wholesale Select 2024 high quality Nickel Slag products in best price from certified Chinese Plating Nickel manufacturers, Metal Nickel suppliers, wholesalers and factory on MadeinChina Nickel Slag Powder Grinder/Powder Crusher/Powder Grinder US$ 60000 / Piece 1 Piece (MOQ) Changsha Wanrong Milling 2021年4月29日 In this study, magnesia–nickel silicate ore was investigated, which contained 083% Ni and antigorite, chlorite, magnetite (Fe3O4), quartz, and mica as the main mineralsExtraction of Nickel from Magnesia–Nickel Silicate Oreslag grinding machine manufacturers/supplier, China slag grinding machine manufacturer factory list, find best price in Chinese slag grinding machine manufacturers, suppliers, factories, exporters wholesalers quickly on MadeinChinaSlag grinding machine Manufacturers Suppliers, China slag grinding 2022年2月3日 The demand for nickel resources has soared with the increase in global consumption of stainless steel []The main sources of nickel are nickel sulfide and laterite nickel ores []With the depletion of nickel sulfide ore, the efficient utilization of laterite nickel ore accounting for approximately 72% of global nickel resources has become more attractive []Characterization of Slag and Growth of Ferronickel Grains

RECYCLING OF NICKELSLAG TAILINGS INTO LIQUID

2021年6月2日 slag Nickel is present in the slag in the form of an (Fe, Ni)S phase which takes the form of individual inclusions that became part of the slag via a mechanical route and cannot be reliably identified The nickeliron inclusions have an Fe:Ni ratio of 1:1 to 5:1 The glassy slag contains 05–2 vol% ironchromium spinel2009年7月1日 Nickel slag, manganese ore, and desulphurisation slag displayed notable H2selectivity (87 to 104) It can be attributed to the presence of lessactive (lattice) oxygen, limiting strong oxygen High pressure oxidative acid leaching of nickel smelter slag 2022年9月28日 Xinjiang is rich in coppernickel ore The solution obtained by leaching of coppernickel ore will produce slag containing nickel and cobalt after removing cobalt by adding NiOOH Recovering valuable metals in nickel–cobalt slag after water washing (hereinafter referred to as NCSW) has important environmental and economic significance The purpose of this Optimizing the Leaching Parameters and Studying the Kinetics of Nickel 2024年7月10日 The rapid development of lithiumion batteries has led to a shortage of cobalt and nickel resources Recycling of nickel and cobalt slag can promote sustainable development and environmental protection In this study, a reductive ammonia leaching method is proposed for the recovery of Ni and Co from nickel and cobalt slag (NCS) with high Ni and Co contents The An Ammonia Leaching Process for the Recovery of Value

Recycling of NickelSlag Tailings into Liquid Products: A

2021年5月11日 We provide an overview of the current status of research on reprocessing of nickel waste tailings, describe the current condition of the tailings, and set forth an important economic goal — freeing up land occupied by tailings and reducing impacts of human activity on the environment We study the structure, chemical composition, and phase composition of 2023年6月9日 The widespread use of nickel metal as a new energy material in recent years has increased the demand to improve its smelting process and the recovery technology of the metal in slag 1 In particular, with the gradual depletion of highgrade nickel ore in China and the higher cost of importing nickel ore, nickel ore with high magnesium concentration has become the Effect of B2O3 on the Melting Characteristics and SlagMatte 2021年10月1日 Fuel to dry carbonated slag {gas, oil or coal} 3 Nickel slag valorization manager, electricity grid manager, local authorities Location of calcination {local or abroad, eg Japan} 2 Cement producer(PDF) Prospective Life Cycle Assessment at Early 2019年6月3日 refractory iron ore Pan et al[10] researched the effect of time, temperature, and amount of coal on magnetic separation and reduction of nickel slag Kinetic studies on nickel slag by Guo et al[11] and thermodynamics on laterite ore by Luo et al[12] showed that the size of metallic iron particles varies greatly in the reductionGrowth Characteristics of Metallic Iron Particles in the

.jpg)

Experimental Study on Preparation of Filling Cementitious

Abstract: The copper nickel smelting slag is mainly the pyrometallurgical smelting slag discharged from the copper nickel ore in the smelting processIts main elements are iron and silicon,with contents of about 40% and 30% respectivelyGenerally,the disposal of copper and nickel smelting slag is mainly stacking and landfill,which wastes land resources and pollutes the 2016年3月30日 Purpose To support the data requirements of stakeholders, the Nickel Institute (NI) conducted a global life cycle impact assessment (LCIA) to show, with indicators, the potential environmental impacts of the production of nickel and ferronickel from mine to refinery gate A metal industry wide agreed approach on byproducts and allocation was applied Methods Life cycle assessment of nickel products Springer2022年1月20日 The nickel and iron recoveries were 8936% and 9587% respectively, which achieved the highly efficient recovery and utilization of iron and nickel of lowgrade laterite nickel ore View Show abstract(PDF) Recycling of chromium sludge to promote2020年2月26日 To overcome the difficulty in the direct reduction of Fe2SiO4 in nickel slag, the isothermal oxidation of the nickel slag was conducted between 300 and 1000 °C Its morphology and phase composition after oxidation at 300–1000 °C for 5–30 min are analyzed by means of Scanning electron microscopy, Xray diffraction, and thermodynamic calculation The results Structure and Phase Changes of Nickel Slag in Oxidation

Nickel industry: Heavy metal(loid)s contamination sources

2021年6月1日 Leaching behaviour of slag and fly ash from laterite nickel ore smelting (Niquelândia, Brazil) Appl Geochem, 64 (2016), pp 118127, 101016/japgeochem201509019 View PDF View article View in Scopus Google Scholar 8 2024年3月13日 The leaching behavior of nickel and iron in limonitetype laterite nickel ore was studied through ammonium hydrogen sulfate atmospheric leaching The leaching temperature, ammonium bisulfate concentration, reaction time, and acid excess rate during the nickel dissolution process were optimized using the response surface methodology (RSM) Leaching Kinetics of LimoniteType Laterite Nickel Ore from 2022年4月21日 Silica was extracted from nickel laterite ore by hydrothermal process with sodium hydroxide as reaction assistant The effects of reaction temperature, reaction time, and NaOHtoore mole ratio on the extraction rate of silica were investigated by a singlefactor experiment The optimal reaction conditions for the preparation of silica were obtained as The Extraction of Silica from Nickel Laterite Ore by Alkaline A strain of Aspergillus niger isolated from lateritic nickel ore of Sukinda (India) was used for leaching purposes The organism was grown in 2% potato dextrose broth (pHBioleaching of copper converter slag using aspergillus

(PDF) Nickel slag waste utilization for road

2020年1月1日 Nickel slag is categorized as Hazardous and Toxic Substances which produced from nickel ore smelting and has large amount of deposits On the other hand, suitable natural materials for road Stedman impact crushers, mills, and grinders are used in nearly every mineral, ore, and mining applicationWhether you are processing iron ore, coal, rock, salt, wood chips, or clay – to name a few – we have your solution to size reduction with our mineral crushing machines industrial ore slag crushersIndustrial Ore, Mineral, Slag Crusher Stedman Machine2023年8月24日 ore in China and the higher cost of importing nickel ore, nickel ore with high magnesium concentration has become the main source of raw materials for nickel smelting A higher MgO concentration increases the slag melting point, weakens the viscous flow characteristics, and makes it more challenging to separate the nickel matte from the slag Effect of B2O3 on the Melting Characteristics and Slag 2017年6月9日 The reduction roasting ammonia leaching process (RRAL) originally defined by Caron (1950) has been extensively applied to treat low grade nickel laterite and a large amount of slagcontaining some Mineralogical Characteristics and Preliminary Beneficiation of Nickel

Penggunaan slag nikel dalam mendukung pembangunan

Visually, nickel slag resembles gravel and sand which can be used as an alternative material Therefore, this literature study aims to determine the characteristics and potential utilization of nickel slag gathered from Indonesian lateritic nickel ore and its2021年5月11日 Nickelcontaining final dump slag was ground to 016 size fraction by means of grinding machine model IDA175, and was subjected to thermochemical treatment in a patented laboratory installation Recycling of NickelSlag Tailings into Liquid Products: A Case 2017年9月26日 M Haslam and L B Arnal "An investigation into the feasibility of extracting scandium from nickel laterite ores" in Proceeding of ALTA 1999 Nickel/Cobalt Pressure Leaching Hydrometallurgy Scandium recovery from slags after oxidized nickel ore 2024年10月29日 Nickel Slag Ball Mill, Grinder, Grinding Machine, Grinding Machinery US$29,0000060,00000 / Piece: 1 Piece (MOQ)Nickel Slag Ball Mill, Grinder, Grinding Machine, Grinding

Complexation leaching of critical and strategic metals from nickel

2023年10月1日 The nickel converter slag was provided by Kalgoorlie nickel smelter and collected from a historic pile The slag was prepared by a combination of jaw crushing, cone crushing and rod milling, followed by pulverised and sieved to produce a sample that passed 75 μm All the samples used in this study were under 75 µm unless specified2019年2月10日 Large volume of metallurgical slag is generated in nickel smelting process as a result of using laterite nickel ore with low content of nickel []It is estimated that production of 1 ton nickel–iron can produce 7–10 tons slag, which large size of land and causes serious environmental pollution []However, the laterite nickel slag still contains valuable metals in the Effect of Ultrasound on the Extraction of Silicon and China Nickel Slag wholesale Select 2024 high quality Nickel Slag products in best price from certified Chinese Plating Nickel manufacturers, Metal Nickel suppliers, wholesalers and factory on MadeinChina Nickel Slag Powder Grinder/Powder Crusher/Powder Grinder US$ 60000 / Piece 1 Piece (MOQ) Changsha Wanrong Milling China Nickel Slag, Nickel Slag Wholesale, Manufacturers, 2021年4月29日 In this study, magnesia–nickel silicate ore was investigated, which contained 083% Ni and antigorite, chlorite, magnetite (Fe3O4), quartz, and mica as the main mineralsExtraction of Nickel from Magnesia–Nickel Silicate Ore

Slag grinding machine Manufacturers Suppliers, China slag grinding

slag grinding machine manufacturers/supplier, China slag grinding machine manufacturer factory list, find best price in Chinese slag grinding machine manufacturers, suppliers, factories, exporters wholesalers quickly on MadeinChina2022年2月3日 The demand for nickel resources has soared with the increase in global consumption of stainless steel []The main sources of nickel are nickel sulfide and laterite nickel ores []With the depletion of nickel sulfide ore, the efficient utilization of laterite nickel ore accounting for approximately 72% of global nickel resources has become more attractive []Characterization of Slag and Growth of Ferronickel Grains 2021年6月2日 slag Nickel is present in the slag in the form of an (Fe, Ni)S phase which takes the form of individual inclusions that became part of the slag via a mechanical route and cannot be reliably identified The nickeliron inclusions have an Fe:Ni ratio of 1:1 to 5:1 The glassy slag contains 05–2 vol% ironchromium spinelRECYCLING OF NICKELSLAG TAILINGS INTO LIQUID 2009年7月1日 Nickel slag, manganese ore, and desulphurisation slag displayed notable H2selectivity (87 to 104) It can be attributed to the presence of lessactive (lattice) oxygen, limiting strong oxygen High pressure oxidative acid leaching of nickel smelter slag

Optimizing the Leaching Parameters and Studying the Kinetics of Nickel

2022年9月28日 Xinjiang is rich in coppernickel ore The solution obtained by leaching of coppernickel ore will produce slag containing nickel and cobalt after removing cobalt by adding NiOOH Recovering valuable metals in nickel–cobalt slag after water washing (hereinafter referred to as NCSW) has important environmental and economic significance The purpose of this 2024年7月10日 The rapid development of lithiumion batteries has led to a shortage of cobalt and nickel resources Recycling of nickel and cobalt slag can promote sustainable development and environmental protection In this study, a reductive ammonia leaching method is proposed for the recovery of Ni and Co from nickel and cobalt slag (NCS) with high Ni and Co contents The An Ammonia Leaching Process for the Recovery of Value