Changchun ore mill mixing

Effects of Adding Calcined Dolomite and Mill Scale to Sinter Mix

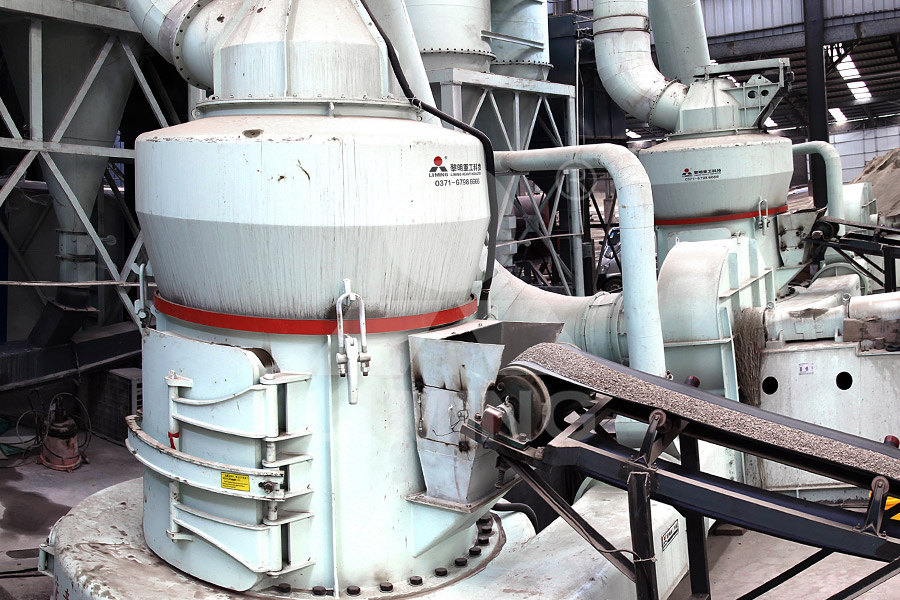

2022年4月8日 As the sources of CaO and FeO, calcined dolomite and mill scale with high potential for use in the steel industry were added to sinter mix to clarify their effects on the 2021年8月25日 In this process, runofmine ore is prepared by one stage primary crushing and one stage medium crushing, then the broken ore is sent to high pressure vertical roller mill for CHANGCHUN GOLD RESEARCH INSTITUTEA dry milling 2020年4月2日 The above measurement was conducted for Ore A and the sole Ore B’, and under the conditions of the addition of Ore B’ by 5, 10, 20, 30% to Ore A and then mixing, the Improving Granulation of Sinter Materials by Using a 2020年1月13日 Mixing/mingling of magmas is an important mode of magmatic evolution, crust–mantle interaction, and compositional exchanges, and the mafic microgranular enclaves Petrology, geochemistry, and zircon U–Pb Wiley Online Library

.jpg)

Numerical simulation of particle mixing and granulation

2023年11月1日 In this study, the granulation of mixed iron ore, coke, and flux in a rotating drum is studied by the discrete element method The results of mixing indicate that the particle Iron ore granulation has been introduced into the steel production process since iron ore agglomeration was proven to have better metallurgical properties and more efficient iron Iron ore granulation for sinter production: Cu mineralization occurs mainly as stockworks or veins in the outer contact zone between tonalite porphyry and Permian metasandstone The oreforming process can be divided into four HOSTED BY Geoscience Frontiers2021年4月27日 To improve the granulation of sinter feed mix, various technologies like twostage granulation process, coating granulation process, wet vertical ball mill and use of Effect of Mixing Preheated Water on Granulation and Iron Ore

Merits of Optimised Milling Configuration on Process

2023年12月11日 added flexibility of feeding both mills simultaneously with fresh feed or feeding the ball mill exclusively, depending on the quality of the fresh ore or downtime on the SAG mill 2023年10月27日 Grinding media play an important role in the comminution of mineral ores in these mills This work reviews the application of balls in mineral processing as a function of the A Review of the Grinding Media in Ball Mills for Mineral © 2024 Lead8 Hong Kong Limited Terms of use Privacy Policy Terms of use Privacy Policy English; 简体; 繁體MixC Changchun Lead8Highquality materials:The rollers of Rubber mixing machine are made of vanadium and titanium metal alloy cold hard cast iron, with hard and wearresistant surface; the transmission system adopts hardened gear reducer, with Rubber Mixing Mill Rubber Machinery For Sale

Crusher,Roll Crusher,Stone Crushing Line,Sand Making

2017年10月11日 Bucket mixer; Spiral ore washer; Energy saving cone ball mill; Cement equipment Cement mill; Rotary kiln; In the process of mining ore ball mill China supplier 05/07; Ball mill can broken different materials 05/07; Featured products West Fourth Ring Chemical Road and Changchun Road intersection 100 meters south2024年11月22日 The MixMill product line has specialized in manufacturing feed processing and mixing equipment for ingredients since 1954 Our reliable products have evolved from many years of experience, making MixMill one of the most widely known manufacturers of feed processing and mixing systems, and grinding and blending machines used by food processing MixMill AT FerrellBM400 Mixer/Mill® (part # 8000M) HighEnergy Ball Mill Highenergy ball mill that grinds up to 10 grams of sample Wide selection of grinding and mixing vials available including hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene, methacrylate, polystyrene, and polycarbonateMixer/Mill – highenergy ball mills, mechanical alloying, mixing 4 天之前 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency Additionally, worn or damaged liners can hinder the grinding process by reducing the effective impact between the Inventory Of Common Faults And Solutions Of Mining Ball Mill

.jpg)

Mobile Mill and Mix Harbro

3 天之前 The UK’s leading on farm mobile mill and mix service is available across the UK, offering flexible, convenient and competitively priced bruising, rolling and treatment Our state of the art vehicles are fast and accurate, processing up to 40 tonnes per hour, which can be discharged to suit your system – cereals can be emptied into bins This advanced cooling system is a standard option across all our open mixing mill models Our rubber open mixing mills come equipped with PA66 BARRIERS (STOCK GUIDES) that can move along the rollers using a hydraulic system This standard feature in all our models direct the compound also allowing for efficient mixing even with smaller quantitiesRubber Open MIxIng MIll Rpmmach2024年1月2日 a pilotscale ball mill (0416 m diameter) and Vale’s industrial mill (518 m diameter), in operation in Vitoria, Espírito Santo, Brazil The pilotscale and the batch mills used were those Population balance model approach to ball mill Manufacturer of Rubber Mixing Mills 1520 kg/hr Rubber Mixing Mill, 25 HP, 23 Kg/hr Two Roll Rubber Mixing Mill With Stock Blender, 75 Hp, 4050 Kg/hr Rubber Mixing Mill With Stock Blender, 75 Hp and 3540 kg/hr Rubber Mixing Mill With Stock Blender, 60 HP offered by G G Engineering Works, Mumbai, MaharashtraRubber Mixing Mills 1520 kg/hr Rubber Mixing Mill, 25 HP

.jpg)

Mill Mix FMF Foods Limited

© 2024 FMF Foods Limited Website by POWER MARKETING 0%2016年2月1日 The purpose of this study is to understand how ore loss and dilution affect the mine call factor, with the aim of subsequently improving the quality of ore mined and fed to the millMonitoring ore loss and dilution for minetomill Agtronix manufactures continuousflow and batching feed mill equipment We offer fully customizable, automated solutions for feed mills We serve industries in the United States, Canada, South America, Europe, Asia, and Australia A Agtronix Feed Mill Equipment Innovative 2023年9月5日 Mixing Mills: Range of SEC Mixing Mills SECMM0613 SECMM1024 SECMM1642 SECMM2260 SECMM2684Mixing Mills, Mixing Mill, Mixing Machinery, Process Plant, Tube Mill

Mill mixing SpringerLink

Mixing rubber compounds on a tworoll mill is common in the following situations: 1 Firstpass mix is accelerated, typically by a fabricator, as part of the preparation for molding, calendering, etc 2 Small batches of specialty compounds are mixed 3 Compound is accelerated on the mill after being dropped from an internal mixer 4Mill Linings provide optimal grinding solutions in major mineral processing plants all over the world DynaWear ® rubber lining system is the preferred lining system for secondary ball mills, regrind mills and scrubbers DynaWear ® is fabricated from rubber and has been specially designed for the mills with a less aggressive application Secondary and Regrind applications Rubber Mill Linings High quality Mining Equipment OMIM Ball Mill Grinding Machines: Exploring the Working Principle, Types, Parts, Applications, Advantages, and Recent Developments Ball mill grinding machines are widely used in various industries for the comminution of materials into fine powders They are versatile tools that offer efficient and reliable grinding and mixing capabilitiesBall Mill Grinding Machines: Working Principle, Types, Parts 2019年9月16日 Efficient mixing room equipment for optimum quality Our range of mixing mills includes machine designs and sizes to suit every requirement, either as a standard addition to a mixing line or for other specialized applications Our highperformance mixing mills feature the highest quality, reliability and profitabilityHighperformance mixing mills for rubber compounding

.jpg)

Mixing Mill(New type )Dalian Hongwei Dispersion Kneader

The Low price Open Mixing Mill in China is a key piece of equipment for rubber and plastic processing It plays an important role in the rubber industry and is mainly used to mix rubber into a uniform rubber compound The mixing process involves putting rubber and other formula raw materials into the drum of the mixer, and then mixing the rubber and other raw materials 1 天前 Mixing mills (also rolling mills) are used for the manufacture of rubber compounds A rubber base material is mixed with several additives, such as fillers, softeners, processing aids and colourants here The two rolls of the rolling mill rotate in the opposite direction For the purpose of mixing, one roll runs faster than the other one Mixing mills DEGUMASCHÜTZ GmbH2023年8月1日 To improve the granulation of sinter feed mix, various technologies like twostage granulation process, coating granulation process, wet vertical ball mill and use of magnetic water have been Numerical simulation of particle mixing and granulation 2015年1月1日 The recorded mill grinding torque in each test is downloaded, and the input net specific energy is calculated Since JKFBC tests were conducted on narrow size fractions, the effect of particle size on breakage results of a copper ore can be clearly demonstrated from Fig 1 a At the same specific energy input level, the larger particles produce larger t 10 valuesA specific energybased size reduction model for batch grinding ball mill

.jpg)

Population balance model approach to ball mill optimization in iron ore

2014年1月1日 The mill product, due to its physical properties, determines the efficiency of subsequent stages of classification, filtration and pelletizing, thus impacting the quality of iron ore pellets2024年6月17日 Also known as tworoll mill mixing, the rubber compounding process makes use of a pair of rotating rolls to process rubber compounds In most cases, you’d find open mill mixing in labs and smallscale production environments Equipment needed here include the rolls themselves, a roll gap, the feed hopper, and simple control systems that A Comprehensive Guide to Rubber Mixing Techniques2024年11月9日 Manganese ore processing plant Tin ore processing plant Tantalum Niobium Processing Plant About Us Contact Us News 上一页 pan mill admin T16:50:42+08:00 9 10 月, 2021 0 条评论 Share This Product, Choose Your Platform! Facebook X pan mill Hengcheng Mining Equipment Co,ltdA staggering 60,000 people turned out for the public opening of CRLand MixC in Changchun It's thrilling to share this early look at the project, which demonstrates ASPECT Studios' expertise in designing for highdensity urban contextsHuge turnout for the public opening of CRLand MixC in Changchun

Recycling of steel plant mill scale via iron ore ResearchGate

2009年8月1日 Mill scale is an iron oxide waste generated during steelmaking, casting and rolling Total generation of mill scale at JSWSL is around 150 t/day and contains 60–70%FeO and 30–35%Fe2O32015年10月22日 College of Earth Sciences, Jilin University, Changchun, China for more papers by this author YunSheng Ren, Corresponding Author YunSheng Ren deposit and the veinletdisseminated Cu–Mo mineralization in the porphyritic granite veins intruding in the orehosting Ordovician strata of the Duobaoshan Formation in the Tongshan Tectonic setting of Triassic magmatic and metallogenic event 2023年4月23日 Comminution is a very important and resultdetermining step in mineral processing This is because further downstream processes in the beneficiation chain depend entirely on it(PDF) Grinding Media in Ball MillsA Review ResearchGate© 2024 Lead8 Hong Kong Limited Terms of use Privacy Policy Terms of use Privacy Policy English; 简体; 繁體MixC Changchun Lead8

.jpg)

Rubber Mixing Mill Rubber Machinery For Sale

Highquality materials:The rollers of Rubber mixing machine are made of vanadium and titanium metal alloy cold hard cast iron, with hard and wearresistant surface; the transmission system adopts hardened gear reducer, with 2017年10月11日 Bucket mixer; Spiral ore washer; Energy saving cone ball mill; Cement equipment Cement mill; Rotary kiln; In the process of mining ore ball mill China supplier 05/07; Ball mill can broken different materials 05/07; Featured products West Fourth Ring Chemical Road and Changchun Road intersection 100 meters southCrusher,Roll Crusher,Stone Crushing Line,Sand Making 2024年11月22日 The MixMill product line has specialized in manufacturing feed processing and mixing equipment for ingredients since 1954 Our reliable products have evolved from many years of experience, making MixMill one of the most widely known manufacturers of feed processing and mixing systems, and grinding and blending machines used by food processing MixMill AT FerrellBM400 Mixer/Mill® (part # 8000M) HighEnergy Ball Mill Highenergy ball mill that grinds up to 10 grams of sample Wide selection of grinding and mixing vials available including hardened steel, stainless steel, tungsten carbide, alumina ceramic, zirconia ceramic, silicon nitride, agate, polystyrene, methacrylate, polystyrene, and polycarbonateMixer/Mill – highenergy ball mills, mechanical alloying, mixing

.jpg)

Inventory Of Common Faults And Solutions Of Mining Ball Mill

4 天之前 Reason: This is a common problem mining ball mills face, resulting in low productivity and low ore processing efficiency One reason may be the improper design of the grinding chamber, which affects the flow of materials and reduces grinding efficiency Additionally, worn or damaged liners can hinder the grinding process by reducing the effective impact between the 3 天之前 The UK’s leading on farm mobile mill and mix service is available across the UK, offering flexible, convenient and competitively priced bruising, rolling and treatment Our state of the art vehicles are fast and accurate, processing up to 40 tonnes per hour, which can be discharged to suit your system – cereals can be emptied into bins Mobile Mill and Mix HarbroThis advanced cooling system is a standard option across all our open mixing mill models Our rubber open mixing mills come equipped with PA66 BARRIERS (STOCK GUIDES) that can move along the rollers using a hydraulic system This standard feature in all our models direct the compound also allowing for efficient mixing even with smaller quantitiesRubber Open MIxIng MIll Rpmmach2024年1月2日 a pilotscale ball mill (0416 m diameter) and Vale’s industrial mill (518 m diameter), in operation in Vitoria, Espírito Santo, Brazil The pilotscale and the batch mills used were those Population balance model approach to ball mill

.jpg)

Rubber Mixing Mills 1520 kg/hr Rubber Mixing Mill, 25 HP

Manufacturer of Rubber Mixing Mills 1520 kg/hr Rubber Mixing Mill, 25 HP, 23 Kg/hr Two Roll Rubber Mixing Mill With Stock Blender, 75 Hp, 4050 Kg/hr Rubber Mixing Mill With Stock Blender, 75 Hp and 3540 kg/hr Rubber Mixing Mill With Stock Blender, 60 HP offered by G G Engineering Works, Mumbai, Maharashtra