HOME→The role of vertical mill in lime rotary kiln The role of vertical mill in lime rotary kiln The role of vertical mill in lime rotary kiln

The role of vertical mill in lime rotary kiln The role of vertical mill in lime rotary kiln The role of vertical mill in lime rotary kiln

.jpg)

The Role of Vertical Shaft Kilns in Optimizing Lime

At the core of lime calcination lies the vertical shaft kiln, a meticulously designed apparatus comprising a vertical shaft, refractory lining, feed system, burner system, and discharge system Each component plays a vital role in ensuring Rotary lime kilns are large steel tubes that are lined on the inside with refractory bricks They are slightly inclined from the horizontal and are slowly rotated on a set of riding rings Lime mud is 22 Lime Kiln Principles And Operations TAPPIThe location of the lime kiln on the Kraft recovery process is shown below WHAT IS A LIME KILN? Rotary kilns are large steel tubes that are lined on the inside with refractory bricks They LIME KILNS, HEAT TRANSFER, CONTROL AND COMBUSTION 2023年2月25日 The rotary kiln is used in many solid processes, including drying, incineration, heating, cooling, humidification, calcination and reduction This widespread application can be Rotary kiln process: An overview of physical mechanisms, models

Rotary kiln process: An overview of physical mechanisms, models

2023年2月25日 Heat transfer plays a critical role in the preparation of clinker for a rotary kiln Often supplied with energy by means of a burner placed at its end, the rotary kiln is the site of 2017年8月1日 This article compares the advantages of modern shaft kilns with other kiln models and explains the functional principle of such lime kilns It also shows new innovative ideas and Lime Shaft Kilns ScienceDirect2019年5月19日 This paper establishes a threedimensional model based on the structure of the existing preheater, and simulates the preheater, optimizes the corresponding structure Analysis and Design of Key Parameters in Intelligent System of This paper covers the modeling and control aspects of Lime Kiln process The lime kiln control in recovery section of paper mill along with heat and mass transfer in reaction, radiation, and Modeling, Control and Instrumentation of Lime Kiln Process: A

Refractories for Lime Calcination SpringerLink

2020年11月29日 Vertical shaft kilns are most efficient kilns found for the calcinations of limestone to produce lime Vertical shaft kiln is a vertical hollow cylindrical furnace fitted with The location of the lime kiln on the Kraft recovery process is shown below The combustion process involves conversion of fuel to oxidized components releasing energy primarily in the 26 Lime Kiln Combustion, Heat Transfer and Optimization 2019Capacity: 501200 t/d (adjustable) Limestone Feeding Size: 2040mm Heat Consumption: approximate 1200 kcal/kg lime Fuel Type: natural gas, coke oven gas, coal powder, etc Features: fully automatic, continuous working 48 weeks Lime Rotary Kiln For Sale – Output: 2001200 T/D2014年1月1日 A Rotary kiln is a cylinder which rotates around its cylindrical axis and acts as a device to exchange the heat The construction, position and alignment of kiln is a essential factor for the Industrial Applications of Rotary Kiln in Various

Processing girth gear of rotary kiln, what material

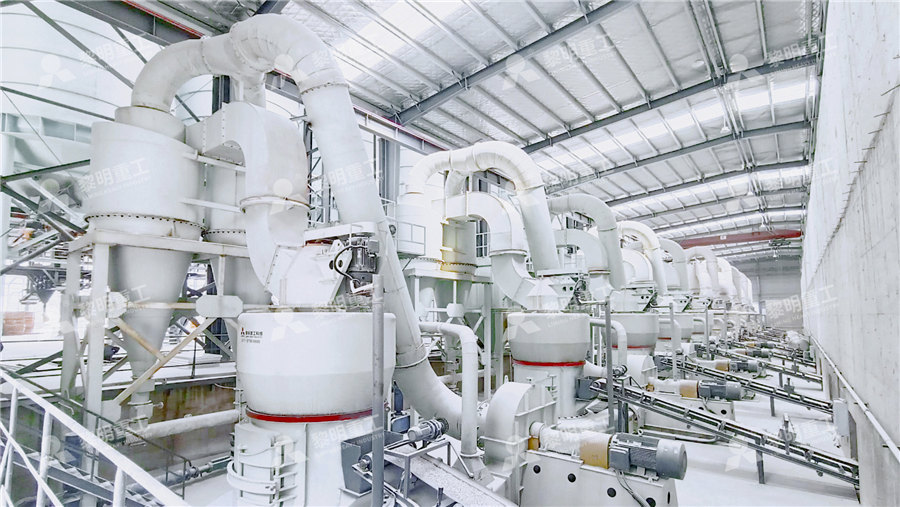

Processing girth gear of rotary kiln, what material wear resistance is high? The girth gear is one of the more commonly used parts in large mechanical equipment (such as rotary kiln, ball mill) Its function is to transmit and change the 2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage Review on vertical roller mill in cement industry its Learn how vertical roller mill technology is transforming the cement industry Explore its benefits, efficiency, and ecofriendly features Discover why it is the goto solution for sustainable cement productionApplication of Vertical Roller Mill in Cement ProductionActive lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Vertical Shaft Lime Kiln for Cement Plant

Rotary Lime Kiln Operation 911Metallurgist

2016年11月29日 The form in which the collected dust can be handled most conveniently in a particular mill must be decided before selecting the dust collecting equipment ROTARY LIME KILN MAINTENANCE David ; November 29, 2016; 4:40 am; Prev Previous Clinker Cooler Next Rotary Kiln Maintenance NextWhy You Choose AGICO Shaft Kiln? AGICO, as an experienced cement manufacturer, has been in the cement industry for almost 20 yearsWe specialize in manufacturing cement mills, cement rotary kilns, and some other cement equipment, with superior quality and high capacityShaft Kiln – Vertical Shaft Kiln – Vertical Kiln AGICO Kiln In The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemThe difference between ball mill and vertical mill in cement grinding Although the vertical mill has high equipment cost, the vertical mill integrates grinding, The important role of vertical roller mills in the cement industry 2 Pages Clinker grinding unit from China lime rotary kiln 4 Pages Cement rotary kiln, 4 Pages Archived catalogs GRM SeriesThe difference between vertical roller mill and ball mill

.jpg)

Lime Rotary Kiln Limestone Rotary Kiln Capacity:

Lime rotary kiln has many advantages in the calcination of lime, it is also known as the lime kiln, and is a professional, strong calcining equipment, Its main advantages include great production capacity, no noise, low energy Service: our company undertakes EPC project including lime kiln design, engineering design, Provision of proprietary equipment, installation and debugging and personnel training, etc 1 Original design and energysaving Vertical Lime Kiln Lime Kiln Manufacturer Output: 4 Lime Rotary Kiln’s cooling method better be forced air cooling 5 There has to be a step to detect the temperature of lime Rotary Kiln’s burning belt 6 Better adopt stepless variable speed motor as lime Rotary Kiln’s main motor Set up A Lime Rotary Kiln To Build Your Lime Calcinating PlantThe lime rotary kiln features an advanced structure and utilizes a lowpressure loss vertical preheater This increases the preheating efficiency of limestone by 2025% and enhances its decomposition rate, achieving efficient lime productionLime Rotary Kiln Roatry Kiln Manufacturer YingYong Machinery

.jpg)

Detection and Diagnosis of Ring Formation in Rotary Lime Kilns

2021年10月21日 this section provides context into the role of the lime kiln in the recovery circuit, describes the problem of ring formation, and presents the available resources to help set the stage for our investigation Kraft Pulping and Rotary Lime Kilns As Figure 1 illustrates, rotary lime kilns (outlined in red)2021年11月2日 3 The vertical kiln has good closure, low heat loss, and relatively low fuel consumption The rotary kiln has a large heat loss due to the long body, but after the use of preheating and cooling technology, the heat energy can be used efficiently, and the fuel consumption has been increased, and the production cost of the product can be controlledLime vertical kiln vs lime rotary kiln Differences and advantagesIn the raw material grinding vertical mill, the heat source for drying the raw materials is the hot gas exhausted from the rotary kiln The cement rotary kiln When operating the vertical roller mill, the operator must control the inlet and outlet air valves to make the air volume of the system in a balanced state, so as not to affect the air pressure at the back end of the rotary kilnVertical Roller Mill Operation in Cement Plant2022年8月1日 A 2D axisymmetric computational fluid dynamics (CFD) model, coupled to a 1D bed model, has been developed to capture the key processes that occur within rotary lime kilns(PDF) CFD Modelling of Calcination in a Rotary Lime Kiln

.jpg)

4 Rotary Kiln Parts Kiln Shell, Kiln Roller, Girth Gear, Kiln Tyre Ring

2022年10月26日 Rotary kiln supplier gives a full guide of rotary kiln spare parts: kiln tyre ring, kiln roller, girth gear and pinion, kiln shell, seal at inlet and outlet, factory price and customized by drawings, ask now!AGICO CEMENT is devoted to being the No1 rotary kiln manufacturer and professional enterprise of import and export trade Our main business is rotary kiln equipment such as cement kiln, lime rotary kiln, and shaft kiln Direct Line: +86 : info@rotarykilnfactoryRole of Kiln Shell Material in Rotary Kiln Alignment and StabilityVertical Lime Kiln Coal burning lime kiln Full name: The important role of vertical roller mills in the cement industry 2 Pages Clinker grinding unit from China 1 Pages CHAENG+Perumin34 Mining Convention+ball mill, rotary kiln+Sep 1620, 2019 1 PagesVertical Lime Kiln of CHAENG DirectIndustryIn recent years, the limestone vertical mill developed and produced by CHAENG has performed well since it was put into the market The important role of vertical roller mills in the cement industry 2 Pages Clinker grinding unit from China lime rotary kiln 4 Pages Cement rotary kiln, 4 Pages Archived catalogsThe importance of vertical roller mill in limestone grinding

.jpg)

Cement Rotary Kiln Design

The length of each part of a rotary kiln is designed based on the inner diameter (D) of the kiln shell 1) The length of the kiln head overhanging section (l 1): l 1 = (12~15) D As the first section of a rotary kiln, l 1 is better not to be designed AGICO Rotary Lime Kiln AGICO Rotary Lime Kilns are specifically designed for efficient, energysaving, and environmentally friendly lime productionOur rotary lime kilns adopt internationally advanced technology and are equipped with vertical preheaters and vertical coolers, providing lime production enterprises with complete turnkey solutionsRotary Lime Kiln Rotary Kiln Lime Production AGICO CEMENTIn summary, the kiln shell and riding rings are vital components of a rotary lime kiln that play a crucial role in maintaining the kiln’s structural integrity and ensuring optimal performance Regular inspection and maintenance are necessary to prevent Rotary Lime Kiln Components Overview 1Download scientific diagram Schematic diagram of a rotary lime kiln from publication: The steadystate simulation results are compared to mill data, and good agreement is foundSchematic diagram of a rotary lime kiln ResearchGate

.jpg)

Investigating the potentials to improve the energy consumption of

2022年11月3日 Sarcheshmeh lime rotary kiln in the south of Iran consumes a lot of thermal energy compared with other rotary kilns As a result, Sarcheshmeh lime kiln is being investigated for the potential to improve energy consumption Experimental data and CFD simulation are both used in this paper The numerical simulation has been performed for three modes to In 2014, a Guangxi building material company purchased φ40×60m rotary kiln and φ24×475m coal mill from Great Wall Machinery, the matched kiln tyres were manufactured by us In August 2014, the kiln tyre produced by CHAENG passes the acceptance of Zhejiang Tongli Company, and got highly praiseRiding ring of rotary kiln Xinxiang Great Wall Machinery Co, Ltd 2018年2月12日 The kiln length predicted by the present model is 574 m as compared to 55 m of the pilot kiln used in the experimental study of Watkinson and Brimacombe (1982, Watkinson, AP and Brimacombe, J Computer Simulation of Heat Transfer in a Rotary Lime Kiln2018年9月1日 Schematic presentation of vertical shaft kiln; (a) preheating zone, (b) reacting zone, and (c) cooling zone Main zones, chemical reactions, and energy use in a shaft kiln [21, 22] Figure 4 Zones (PDF) Energy optimisation of vertical shaft kiln operation in the

Lime Rotary Kiln For Sale – Output: 2001200 T/D

Capacity: 501200 t/d (adjustable) Limestone Feeding Size: 2040mm Heat Consumption: approximate 1200 kcal/kg lime Fuel Type: natural gas, coke oven gas, coal powder, etc Features: fully automatic, continuous working 48 weeks 2014年1月1日 A Rotary kiln is a cylinder which rotates around its cylindrical axis and acts as a device to exchange the heat The construction, position and alignment of kiln is a essential factor for the Industrial Applications of Rotary Kiln in Various Processing girth gear of rotary kiln, what material wear resistance is high? The girth gear is one of the more commonly used parts in large mechanical equipment (such as rotary kiln, ball mill) Its function is to transmit and change the Processing girth gear of rotary kiln, what material 2021年1月1日 Grinding Mill Vertical Roller Mill or Ball Mill: The reclaimed raw mix fed to Raw Mills, for drying and fine grinding of Raw meal for kiln feed: 4: Coal Grinding: Grinding Mill Vertical Roller Mill or Ball Mill: Coal is ground in Coal mill, which is a fuel for use in Kiln firing: 5: Pyro Section, Clikerization: In line calciner six stage Review on vertical roller mill in cement industry its

Application of Vertical Roller Mill in Cement Production

Learn how vertical roller mill technology is transforming the cement industry Explore its benefits, efficiency, and ecofriendly features Discover why it is the goto solution for sustainable cement productionActive lime vertical kiln equipment supporting Calcination of limestone Qualified limestone goes to the top of the preheater through the belt conveyor, and the material is introduced into the body of the preheater from the silo at the top of the preheater through the discharge chute, and at the same time, the hightemperature flue gas from the rotary kiln preheats the material to 600°C Vertical Shaft Lime Kiln for Cement Plant2016年11月29日 The form in which the collected dust can be handled most conveniently in a particular mill must be decided before selecting the dust collecting equipment ROTARY LIME KILN MAINTENANCE David ; November 29, 2016; 4:40 am; Prev Previous Clinker Cooler Next Rotary Kiln Maintenance NextRotary Lime Kiln Operation 911MetallurgistWhy You Choose AGICO Shaft Kiln? AGICO, as an experienced cement manufacturer, has been in the cement industry for almost 20 yearsWe specialize in manufacturing cement mills, cement rotary kilns, and some other cement equipment, with superior quality and high capacityShaft Kiln – Vertical Shaft Kiln – Vertical Kiln AGICO Kiln In

The difference between ball mill and vertical mill in cement grinding

The difference between ball mill and vertical mill in cement grinding Over the last three decades the vertical roller mill has become the preferred ball mill for grinding of raw materials The grinding efficiency of the vertical roller mill combined with an ability to dry, grind and classify within a single unit gives the vertical roller mill a decided advantage over a ball mill systemAlthough the vertical mill has high equipment cost, the vertical mill integrates grinding, The important role of vertical roller mills in the cement industry 2 Pages Clinker grinding unit from China lime rotary kiln 4 Pages Cement rotary kiln, 4 Pages Archived catalogs GRM SeriesThe difference between vertical roller mill and ball mill