Limestone 2200 anthracite lignite grinding mill

.jpg)

China Limestone Grinding Mill, Limestone Grinding Mill

China Limestone Grinding Mill wholesale Select 2024 high quality Limestone Grinding Mill products in best price from certified Chinese Mill manufacturers, Milling Machine suppliers, Limestone grinding mill is mainly suitable for ultrafine powder processing of noninflammable and explosive brittle materials with medium and low hardness and Mohs hardness ≤6, such as calcite, chalk, limestone, calcite, carbon black, Limestone grinding mill Hengtu Machinery5 天之前 The limestone grinding production line grinds limestone into powders of different fineness through crushing, grinding, classification, and other processes to meet the needs of Limestone Grinding Mill Plant TAYMACHINERYLignite Processing SiteLIMING HEAVY INDUSTRY CO, LTD This project is mainly equipped with MTW175 European grinding mill and other ancillary equipment The processing material Lignite Processing SiteLIMING HEAVY INDUSTRY CO, LTD

.jpg)

How to choose a limestone grinding mill

2024年1月18日 Crushing: Limestone large chunks are crushed by a crusher to a feed fineness that can enter the milling machine (15mm50mm) Milling: After crushing, small pieces of limestone are sent to the storage bin through an Sourcing Guide for Limestone Mills: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufactuChina Limestone Mills, Limestone Mills Wholesale, 2022年8月26日 Limestone Grinding Mill Working Principle Limestone grinding mill is composed of grinding host, grading screening, product collection and other parts The host adopts the overall cast base structure and can adopt the Which Grinding Mill Is Suitable For Processing China Limestone Grinder Mill wholesale Select 2024 high quality Limestone Grinder Mill products in best price from certified Chinese Steel Mill manufacturers, Industrial Mill suppliers, China Limestone Grinder Mill, Limestone Grinder Mill

Coal mill, gypsum mill, clay mill, etc Pfeiffer

MPS vertical mill from Pfeiffer is the ideal allrounder Grinding of coal, petcoke, clay, limestone, quicklime, gypsum, and many other materials17 Lignite Combustion – US Environmental Protection Agency In a pulverized lignitefired boiler, SCCs = pulverized coalfired boilers, 10100301, Boiler Design And Operating Variables Affecting Uncontrolled » More detailed! Coal Firing Systems – Hitachi w Polsce Designed as coal bunker dischargers, the mill feeders supply the pulverizers with In hard coal boiler units layout of coal mill /bunker for lignite fired boilers5 天之前 A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturing The plant involves several stages and equipment to achieve Limestone Grinding Mill Plant TAYMACHINERY2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine

COAL GRINDING IMPS: more than meets the eye Gebr

2016年12月19日 per cent and, on the other, ball mills whose share is recorded at just over 10 per cent1 Mill design features and benefits GPSE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as under air or inert gas atmosphere SystemThe Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill Clirik Grinding Mill2024年7月11日 1 Bulk material first with a broken jaw or impact crusher crushing To fit into the grinding mill size; 2 After the break, particle size suitable materials are transferred to the European version of the Tshaped device or mediumspeed Tshaped grinding mill, LM milling machines and other coal milling equipment; 3coal grinding mill, coal pulverizer machine, coal powder 5 天之前 slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller mills

What is Limestone Grinding Mill SBM Mill Crusher

2023年5月15日 A limestone grinding mill is a machine that grinds and powderizes limestone It is very useful in the manufacture of cement, glass, steel and other industrial products that require finely ground limestone Limestone enters the mill where it is processed and crushed by grinding media (balls or rollers) Separators collect the resulting powders 2024年1月29日 Limestone is a common mineral, typically composed mainly of calcium carbonate (CaCO3) After grinding limestone into powder, it has various uses depending on the fineness of the powder and its chemical properties Here are some common uses: Manufacture of Building Materials: Limestone powder is often used in the production of cement The How to choose limestone grinding mill? SANDMINE2022年4月20日 Before the limestone is pulverized, it needs to be crushed by a crusher to the particles that match the feed size of the mill Then it is sent to the limestone grinding mill at a constant speed through a vibrating screen for grinding The ground limestone is sorted by the separator at the upper end of the millLimestone crushing and grinding production line SBM 2020年8月12日 This study shows the performance of a currently running vertical roller coal mill (VRM) in an existing coalfired power plant In a power plant, the coal mill is the critical equipment, whose An investigation of performance characteristics

Beater Wheel Mill PDF Lignite Mill (Grinding)

2023年11月5日 This document discusses beater wheel mills used in lignitefired boilers It includes: 1 An overview of beater wheel mills, including their components, typical sizes and capacities, and the comminution process within 2024年7月1日 (granulated blast furnace slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller pressPicture: Loesche GmbH, Germany CEMENT SikaGrind® 2013年5月15日 The objective of this study was to analyze dry grinding kinetics of three different solid fuels in terms of selection and breakage distribution functions values using a batch laboratory ball parisons of Dry Grinding Kinetics of Lignite, Bituminous 2020年12月3日 Benefits of Clirik Limestone Powder Grinding Mill Machinery 1 High efficiency:Under the same final size and power, the product capacity of ultrafine mill is twice than jet mill and agitation mill 2 Longer lifetime of spare parts:The roller and ring are made of special material, which improve the grinding efficiency a lotFor same material and final size, the Limestone Powder Grinding Mill Machinery

.jpg)

6 Types Of Limestone Dry Powder Grinder Machines

2024年8月9日 Working Principles Feeding: Limestone is fed into the machine through a feeder, which controls the amount of material entering the grinding chamber Grinding: The material is crushed between grinding rollers and rings (in Raymond and Vertical mills) or by grinding media (in Ball mills)The material is continuously ground until it reaches the desired fineness2022年12月22日 Limestone Ball mill can devide into 2 types, wet ball mill and dry ball mill Ball mill is a mineral processing machine for milling the materials into powders after they are crushed The materials are transferred to the grinding chamber through the quill shaft uniformly There are ladder liner and rippleliner and different specifications of Limestone Ball MillGulin Least News Optimizing manganese ore sinter plants: process parameters and design implications » The More » crushed stone cost per yard » small maize grinding mill for sale in south africa » all the different uses of limestone » bond ball mill work index » rocks and minerals shop india Contact Us Tel: 8621distinction between peat, lignite, bituminous and anthracite 2011年2月1日 Download Citation A comparison of the results obtained from grinding in a stirred media mill lignite coal samples treated with microwave and untreated samples Various studies have been carried A comparison of the results obtained from grinding in a

Reducing CO2 emissions through cement grinding

2022年8月22日 Lower cement grinding energ y consumption While many efforts have concerned the kiln and fuels, optimisation of grinding can also play a significant role in cutting CO 2 Energy consumption can be reduced by mill system design and optimisation, selection of cement grade and by improving grindabilityLimestone ball mill is a horizontal and cylindrical rotating device with two grinding methods: dry grinding and wet grinding A certain number of steel balls are filled in the cylinder as grinding media, and with the rotation of the cylinder, the Limestone Ball Mill Limestone Grinder AGICO 2024年10月12日 Lignite plays a critical role in the country’s energy supply, accounting for a substantial portion of electricity generation Unlike highergrade coals like anthracite and bituminous coal, lignite is less energydense but cheaper to extract due to its proximity to the surface, making it an economically viable option for power productionLignite Crushing in Poland: Challenges and TechnologyVertical mill is widely used for pulverized coal preparation system in power plant, cement plant, metallurgy industry, chemical plant, etc It could be used to grind bituminite, meagre coal, and anthracite lignite with high moisture under Vertical mill for coal pulverizing in power plant

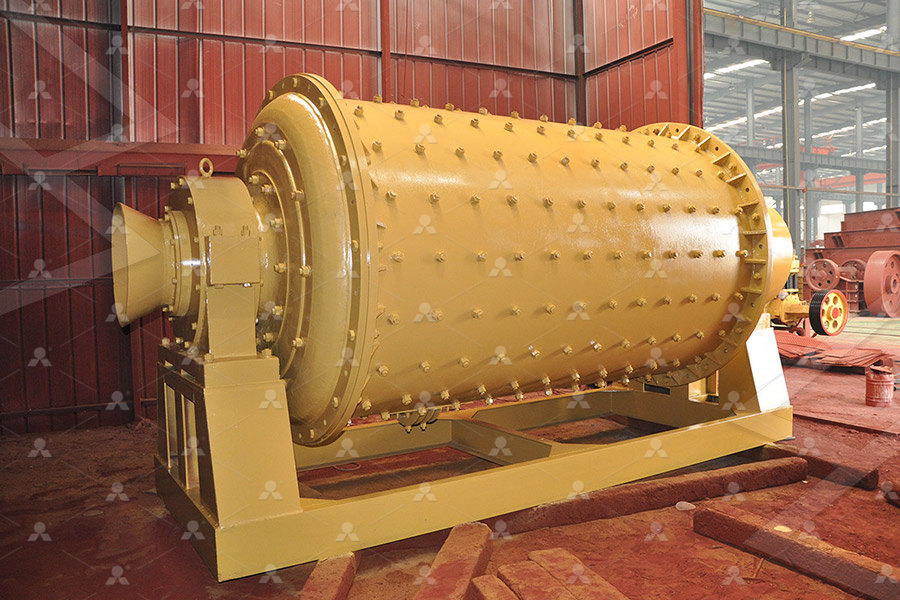

Limestone Grinding Mill, Limestone Mill,Limestone Grinding

2024年10月16日 The limestone grinding mill uses the principle of mechanical crushing to grind large pieces of limestone into fine particles It is an important equipment for deep processing of limestone There are two main types of limestone grinding mills: MTW European Type grinding mill and LM vertical roller mill 2017年2月20日 Grinding Mill Specifications Data According to formula 423/√d, where d is equal to internal shell diameter within new liners In this case the thickness used was 60 mm for small mill sizes up to and including 2940 and 80 mm for larger millsGrinding Mill Design Ball Mill ManufacturerThe limestone grinding mill, also known as lime grinding, is a machine used to grind limestone into powder formLimestone remains in lumpy form after being processed through the limestone crusherBefore entering the calcination stage, limestone needs to be ground into powder form using a limestone grinding mill The main component of limestone is calcium carbonate, which Limestone Grinding Mill Solution Adjustable Powder FinenessHOME > APPLICATIONS > MINERALS > LIMESTONE GRINDING Limestone Grinding The main application for limestone is as hydrated lime (calcium hydroxide) for mortar or plaster preparation On a smaller scale, lime is additionally used as a fertilizer, for wastewater treatment or as an additive in the food industry (for example as a neutralizing agent or acidityLIMESTONE GRINDING Bauermeister Size Reduction

Reprint from ZKG 3 Gebr Pfeiffer

2016年12月19日 grinding lignite with feed moistures of as much as 45 % Depending on this high feed moisture the mill rating is determined by the drying process whereas for anthracite, hard coal and petcok e the rating of the mill is determined by the grinding process The great variety of solid fuel properties,2021年6月25日 17 Lignite Combustion 171 General15 Coal is a complex combination of organic matter and inorganic ash formed over eons from successive layers of fallen vegetation Coals are classified by rank according to their progressive alteration in the natural metamorphosis from lignite to anthracite Coal rank depends on the volatile17 Lignite Combustion US Environmental Protection 2014年7月12日 The document discusses grinding technology for limestone using ball mills It covers: 1 The properties and applications of limestone powder 2 Wet and dry grinding processes 3 Different types of grinding circuits including classical ball mill, airswept mill, birotator, and compound mill circuits 4 Details of mill internals such as ball charges and linings for Grinding Technology of Limestone With Ball Mills17 Lignite Combustion – US Environmental Protection Agency In a pulverized lignitefired boiler, SCCs = pulverized coalfired boilers, 10100301, Boiler Design And Operating Variables Affecting Uncontrolled » More detailed! Coal Firing Systems – Hitachi w Polsce Designed as coal bunker dischargers, the mill feeders supply the pulverizers with In hard coal boiler units layout of coal mill /bunker for lignite fired boilers

Limestone Grinding Mill Plant TAYMACHINERY

5 天之前 A Limestone Grinding Mill Plant is a facility designed to process limestone into fine powder for various applications Limestone is a sedimentary rock primarily composed of calcium carbonate (CaCO₃) and is widely used in industries such as construction, agriculture, and manufacturing The plant involves several stages and equipment to achieve 2021年9月13日 The limestone ultrafine mill machine is a highly efficient industrial grinding mill It can grind limestone into a fine powder (1503000 mesh), and the fineness can be adjusted freely In addition, it can also grind 100+ Limestone Ultrafine Mill Machine SBM Ultrafine 2016年12月19日 per cent and, on the other, ball mills whose share is recorded at just over 10 per cent1 Mill design features and benefits GPSE supplies standalone MPS coal grinding mills as well as complete coal grindingdrying systems Both mill and grinding system can be operated under pressure or suction as well as under air or inert gas atmosphere SystemCOAL GRINDING IMPS: more than meets the eye GebrThe Limestone powder ultrafine grinding mill was made by Clirik in 2016 This is a professional processing of limestone powder grinding machines The fineness of the finished product can be adjusted between 325 mesh and 3000 mesh Limestone Powder Ultrafine Grinding Mill has HGM80, HGM90, HGM100, HGM125,HGM1680 five modelsLimestone Powder Ultrafine Grinding Mill Clirik Grinding Mill

.jpg)

coal grinding mill, coal pulverizer machine, coal powder

2024年7月11日 1 Bulk material first with a broken jaw or impact crusher crushing To fit into the grinding mill size; 2 After the break, particle size suitable materials are transferred to the European version of the Tshaped device or mediumspeed Tshaped grinding mill, LM milling machines and other coal milling equipment; 35 天之前 slag, fly ash, pozzolanes, limestone etc) The grinding of the finished cement consumes approximately one third of the total electrical energy of a cement plant Vertical Roller Mills (VRM) have a clearly higher energy efficiency than ball mills, even if the ball mill is combined with a roller press This and further argumentsSikaGrind® for vertical roller mills2023年5月15日 A limestone grinding mill is a machine that grinds and powderizes limestone It is very useful in the manufacture of cement, glass, steel and other industrial products that require finely ground limestone Limestone enters the mill where it is processed and crushed by grinding media (balls or rollers) Separators collect the resulting powders What is Limestone Grinding Mill SBM Mill Crusher2024年1月29日 Limestone is a common mineral, typically composed mainly of calcium carbonate (CaCO3) After grinding limestone into powder, it has various uses depending on the fineness of the powder and its chemical properties Here are some common uses: Manufacture of Building Materials: Limestone powder is often used in the production of cement The How to choose limestone grinding mill? SANDMINE

Limestone crushing and grinding production line SBM

2022年4月20日 Before the limestone is pulverized, it needs to be crushed by a crusher to the particles that match the feed size of the mill Then it is sent to the limestone grinding mill at a constant speed through a vibrating screen for grinding The ground limestone is sorted by the separator at the upper end of the mill