Process of starting a bentonite factory

.jpg)

Process Development Essential to Bentonite

5 天之前 The diverse nature of bentonite, paired with its potential for variation make a thorough process development program such as those carried out in the FEECO Innovation Center crucial to those producing bentonite products Bentonite can be processed in several ways to optimize properties for the individual uses Clariant's Adsorbents business operates 28 production sites that turn the raw bentonite clay into consistent quality products for a variety of our Bentonite production Clariant Ltd2013年1月1日 Special use of bentonite, where its absorbing properties are employed to provide watertight sealing is for an Find, read and cite all the research you need on ResearchGate(PDF) Bentonite processing ResearchGate2024年11月20日 Bentonite processing process The feeder sends the bulk bentonite to the jaw crusher for coarse crushing first, and the coarsely crushed bentonite material is sent to the impact crusher by the belt conveyor for Bentonite production process and equipment

Bentonite production

Bentonite can be processed in several ways to optimize properties for the individual uses Clariant's Adsorbents business operates 28 production sites that turn the raw bentonite clay 2023年11月21日 Establishing a bentonite granules production line requires careful planning, equipment selection, and operational considerations In this guide, we will walk you through How to setup a bentonite granules production line nbssiFrom mining the raw materials to processing them to tailoring them into customerspecific solutions, we provide you with 360° of service across the entire value chain Bentonite is a clay material that is quite abundant on earth Bentonite Bentonite exporation and mining Clariant Ltd2020年4月14日 A new process for manufacturing organically compounded bentonite was developed successfully based on the organic intercalation and layered structure of bentonite Synthesis, characterization and properties of organically

.jpg)

Bentonite IMA Europe

2020年9月8日 applications, bentonite is purified by removing the associated gangue minerals, or treated with acids to produce acid activated bentonite (bleaching earths), or treated with 2019年2月23日 In this paper, a modified procedure for bentonite purification and a new method for the quantitative characterization of bentonite based on smectite content in bentonite are Modified Method for Bentonite Purification and2005年11月14日 To speed up the backfill saturation, the salinity of the Äspö water was increased adding NaCl and CaCl 2 up to 16 g/L of salt concentration (50 / 50 by mass) Main chemical species present in the injected water, used to saturate the backfill, are shown in Table 1The actual number of chemical species in the bentonite–fluid system is obviously bigger, as A hydrogeochemical analysis of the saturation process with salt water 2023年9月11日 It is conceivable that bentonite dissolution and subsequent diffusion of Mg and/or thermalinduced migration towards the heater (JodinCaumon et al, 2012) could lead to Mg enrichment; however, to the knowledge of the authors, this process has not been described as part of a model study to date The possibility of predicting this reaction would Chemical and mineralogical reactions of bentonites in

.jpg)

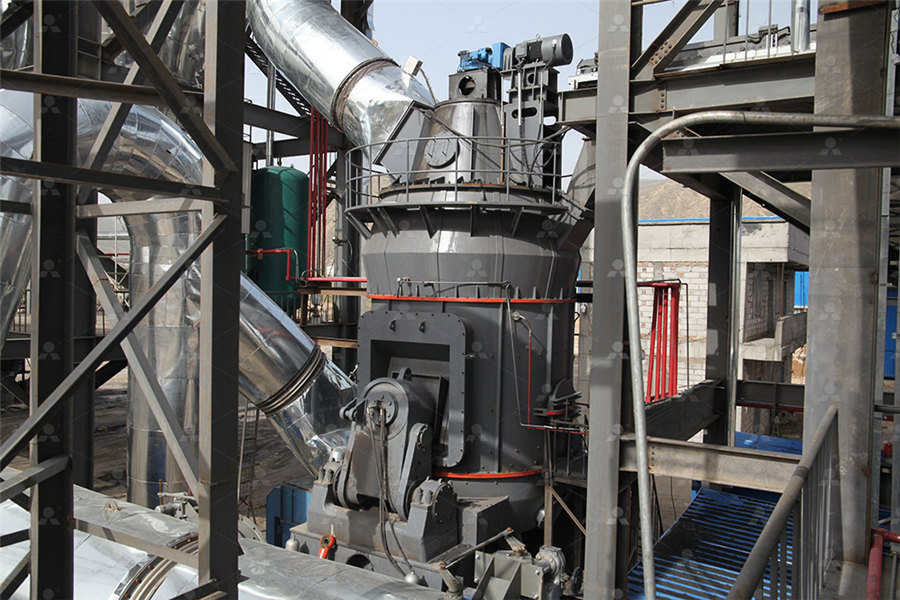

Bentonite Processing Methods And Required

5 天之前 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentoniterich ore with montmorillonite content of more than 80%This method is to dry the raw ore in the sun, air dry it naturally or dry it in When the mixing process was finished, backfill was stored and its water content was 229 C Mata et al / Engineering Geology 81 (2005) 227–245 Old part excavated by normal blasting Bentonite blocks and bentonite pellets New part excavated by careful blasting D1 Drainage material D2 D3 D4 D5 D6 A1 A2 A3 D7 A4 D8 D9 A5 A6 28 m Concrete wall D12 A hydrogeochemical analysis of the saturation process with 2023年10月21日 conditions for the clarification process were: dose of bentonite — 203 g 25L1, time — 45 min, temperature — 20±1 °C, stirring time — 60 s, centrifugation time — 3 min and spin THE PARTICULARITIES OF THE CLARIFICATION PROCESS Jetta Bentonite brand of Keshav Minerals Company in india is a leading provider of highquality bentonite products for various industrial applications With 10 years of experience and expertise in the field, we are committed to delivering superiorgrade bentonite that meets the needs of our clients Our range of products includes sodium bentonite, calcium bentonite, and polymer Your Bentonite Manufacture II Exporter from India II Jetta

Get HighQuality bentonite factory at Remarkable Prices

Hot Selling Cat Litter Bentonite Factory OEM / ODM Multi Fragrance DustFree Strong Clumping Ball Shaped Bentonite Cat sand $074$100 Min Order: 625 bags Previous slide Next slide Factory Premium Bentonite Cat Litter Strong Clumping DustFree Bentonite For Cat Litter Ready to In the process of starting a factory, many factory owners face the issue of not finding the right types of machinery and some of the time they don't know from where they will get the machinery In India, Pune ranks on top when it comes to Machinery's Hub for manufacturing industries With a strong industrial base and a favorable business How to Start a Factory From Concept to Construction2023年9月8日 The bentonite suspension was prepared as follows: 500 g of fine bentonite sample was mixed with water (4 dm 3 ) in 5 litre container After mixing the suspension forBentonite clay suspension coagulation process and 5 天之前 This is further complicated by bentonite’s significant variation – even within the same deposit As such, bentonite process development testing is a key aspect of developing a successful processing operation Bentonite Characteristics Bentonite is a member of the smectite group of minerals and is primarily made up of montmorilloniteProcess Development Essential to Bentonite Processing Operations

.jpg)

Synthesis, characterization and properties of organically

2020年4月14日 A new process for manufacturing organically compounded bentonite was developed successfully based on the organic intercalation and layered structure of bentonite The main steps in the proposed process included wet sodium activation of bentonite ore, organic compounding and highpressure roll grinding The optimum procedure is recommended as 2021年11月10日 The study reveals that bentonite clay has large surface area due to similar structure with montmorillonite and it is found that the functionality of bentonite can be increased by increasing total Modification of bentonite clay its applications: 2024年10月13日 High Yield Bentonite Production Process Bentonite settlings generally are taken advantage via way of via means of excavating Bentonite can still noticeably be a solid once extracted regardless of its dampness levels High Yield Bentonite Iran Bentonite CoCasting Bentonite Casting Bentonite is a sodium bentonite with high natural properties specifically designed for the sand molding process It offers excellent moisture resistance, high strength, and high thermal values It has a consistent compactibility level (40) that sets it apart from other bentonite products Casting foundries benefit from its high thermal durability, reduced bentonite Casting Bentonite RBS Bentonit

.jpg)

Bentonite production Clariant Ltd

Bentonite clay is a raw material from nature and further processing is needed to turn the raw clay into products for final applications Process and production Turning bentonite clay into quality products Bentonite can be processed in several ways to optimize properties for the individual uses Clariant's Adsorbents business operates 28 In the mainly practiced twostage reducing process, the round wood is first chipped into wood chips The size of the chips determines the length of the later flakes or fibres Learn more about Chipper, Metal Detector in production step Chipping Flaking A knife ring flaker produces the flakes from the wood chips Particleboard manufacturing process processingwood2010年1月20日 Optimization studies were carried out for the synthesis of zeolite A by a hydrothermal method using alkaliactivated bentonite as raw material The process of alkali fusion activation and Synthesis of Zeolite of Type A from Bentonite by Alkali 2018年7月11日 Balling process: the gre en pelle t is the roll ed pellet wi thout a ny thermal process It is ob tained under stri ct control of moi sture and has a sphe rical sha pe and diameter of 8 – 16 mm;(PDF) Iron Ore Pelletizing Process: An Overview ResearchGate

.jpg)

Bored pile construction process Office BuildingPort

23 小时之前 The rinsing process lasts 2030s, the bentonite solution must be continuously compensated during the washing process Then release the plumb line to measure the depth, if the bottom depth of the borehole is guaranteed (settlement 10cm), then just check the bentonite solution removed from the bottom of the borehole2018年7月11日 The iron ore production has significantly expanded in recent years, owing to increasing steel demands in developing countries However, the content of iron in ore deposits has deteriorated and lowgrade iron ore has been processed The fines resulting from the concentration process must be agglomerated for use in iron and steelmaking This chapter Iron Ore Pelletizing Process: An Overview IntechOpen2023年12月18日 Granular bentonite has been considered as candidate sealing material of various technological gaps in deep geological repository of highlevel radioactive waste (HLW) Large interpellet pores inside the granular bentonite Homogenization of a granular bentonite 2023年11月9日 The swelling process of bentonite is vital for judging the time required for completing the swelling, estimating the engineering safety, and organizing the construction plan Many factors affect the swelling process, and the underlying mechanisms still require to be clearly explained In this paper, the swelling process of commercial bentonite in different molar Mechanism Explanation of Influence of Dry Density and

THE EFFICACY OF BENTONITE FEED ADDITIVES

2021年10月2日 This review aimed to discuss the effect of dietary bentonite as feed additives on laying hens performance and egg qualities The prohibition of antibiotics use could potentially have several 2008年4月1日 A bentonite clay mineral was pillared with solid Al and AlZr polymers in molar ratios of 97:3 to 90:10 We used ultrasonication for Al intercalation in a highly concentrated suspensionSynthesis of pillared bentonite starting from the Al–Fe 2022年9月20日 Schematic representation of the assembly for GAPliquid tests (injection opposite to gap) Bentonite swelling into a void under suction or water flow2021年12月22日 Bentonite is a clay with interesting surface properties (affinity for water, adsorption capacity for electropositive compounds) The characteristics and clarifying properties of bentonite (PDF) Exploitation of Bentonite for Wastewater Treatment

Transformation of bentonite used in green sand molds

2021年6月1日 Green sand molds in foundry use bentonite as a binder During the casting process, the heat transferred to the surrounding sand in the mold leads to the degradation of bentonite structure, thereby 2020年3月1日 As a starting mineral, a natural bentonite from Valle del CaucaColombia was used, where part of its characteristics has already been reported [25,26] Its general formula is: Si 4 O 10 (OH) 2 (Al 3,33 Mg 0,67)Si 4 O 10 (OH) 2 (Na, K) 0,67 which classifies it as a montmorillonitic type sodium bentonite In addition, its potential has been Potentialization of bentonite properties as support in acid 2019年11月26日 Bentonite:Fe2 Ob entonite:F eO 2 + +⇒ xy (3) 31 Morphology The image of SEM of bentonite and FeB is presented in Fig 1 The SEM image of parent bentonite (Fig 1a) shows a layered structure with a typical sheetlike morphology After the solidstate ion exchange, the original structure of bentonite remains The only observed difference is theCatalytic activity of Femodified bentonite in 2021年2月1日 Investigations indicated that the bentonite pellets would undergo a complex hydromechanical coupling process during the longterm operation of a repository, eg, the infiltration of groundwater Analysis of boundary friction effect on the homogenization process

A hydrogeochemical analysis of the saturation process with salt water

2005年11月14日 To speed up the backfill saturation, the salinity of the Äspö water was increased adding NaCl and CaCl 2 up to 16 g/L of salt concentration (50 / 50 by mass) Main chemical species present in the injected water, used to saturate the backfill, are shown in Table 1The actual number of chemical species in the bentonite–fluid system is obviously bigger, as 2023年9月11日 It is conceivable that bentonite dissolution and subsequent diffusion of Mg and/or thermalinduced migration towards the heater (JodinCaumon et al, 2012) could lead to Mg enrichment; however, to the knowledge of the authors, this process has not been described as part of a model study to date The possibility of predicting this reaction would Chemical and mineralogical reactions of bentonites in 5 天之前 Dry beneficiation is generally used to process bentonite with better raw ore quality, or bentoniterich ore with montmorillonite content of more than 80%This method is to dry the raw ore in the sun, air dry it naturally or dry it in Bentonite Processing Methods And Required When the mixing process was finished, backfill was stored and its water content was 229 C Mata et al / Engineering Geology 81 (2005) 227–245 Old part excavated by normal blasting Bentonite blocks and bentonite pellets New part excavated by careful blasting D1 Drainage material D2 D3 D4 D5 D6 A1 A2 A3 D7 A4 D8 D9 A5 A6 28 m Concrete wall D12 A hydrogeochemical analysis of the saturation process with

.jpg)

THE PARTICULARITIES OF THE CLARIFICATION PROCESS

2023年10月21日 conditions for the clarification process were: dose of bentonite — 203 g 25L1, time — 45 min, temperature — 20±1 °C, stirring time — 60 s, centrifugation time — 3 min and spin Jetta Bentonite brand of Keshav Minerals Company in india is a leading provider of highquality bentonite products for various industrial applications With 10 years of experience and expertise in the field, we are committed to delivering superiorgrade bentonite that meets the needs of our clients Our range of products includes sodium bentonite, calcium bentonite, and polymer Your Bentonite Manufacture II Exporter from India II Jetta Hot Selling Cat Litter Bentonite Factory OEM / ODM Multi Fragrance DustFree Strong Clumping Ball Shaped Bentonite Cat sand $074$100 Min Order: 625 bags Previous slide Next slide Factory Premium Bentonite Cat Litter Strong Clumping DustFree Bentonite For Cat Litter Ready to Get HighQuality bentonite factory at Remarkable PricesIn the process of starting a factory, many factory owners face the issue of not finding the right types of machinery and some of the time they don't know from where they will get the machinery In India, Pune ranks on top when it comes to Machinery's Hub for manufacturing industries With a strong industrial base and a favorable business How to Start a Factory From Concept to Construction

Bentonite clay suspension coagulation process and

2023年9月8日 The bentonite suspension was prepared as follows: 500 g of fine bentonite sample was mixed with water (4 dm 3 ) in 5 litre container After mixing the suspension for5 天之前 This is further complicated by bentonite’s significant variation – even within the same deposit As such, bentonite process development testing is a key aspect of developing a successful processing operation Bentonite Characteristics Bentonite is a member of the smectite group of minerals and is primarily made up of montmorilloniteProcess Development Essential to Bentonite Processing Operations