Semiautogenous mill and ball mill

.jpg)

Autogenous Grinding Semi Autogenous

2017年7月20日 Semiautogenous grinding is applied when fine crushing could cause severe problems or when ore is variable in hardness or competency Figure 2 shows a typical conventional crushinggrinding circuit with three A new large concentrator unit typically consists of a semiautogenous grinding mill, high pressure grinding rolls, two ball mills, and a flotation circuit It can treat up to 170 000 tonnes of ore per Semi Autogenous Grinding Mill an overview ScienceDirect2020年1月1日 CIRCUIT AND MODEL IAMGOLD Corporation operates Westwood mine located in northwestern Quebec, Canada The grinding circuit, represented in Figure 1, comprises a Systematic calibration of a simulated semiautogenous/ballmill 1986年5月1日 In spite of initial difficulties, large autogenous and semiautogenous mills have reached an acceptable level of technology that provides the mineral engineer with a reliable, Semiautogenous mill liners: Designs, alloys, and maintenance procedures

R)8OC`6F[ZIB.jpg)

PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER

2021年6月17日 The authors analyze the influence of the semiautogenous (SAG) mill parameters on the mill grinding efficiency, energy consumption and the tangential cumulative 2023年6月7日 The volume of added steel balls usually accounts for 2–20% of effective volume of autogenous mill Semiautogenous mill has flexible loop, is highly adaptable to ore, and can Autogenous Mill SpringerLink2015年1月1日 This paper discusses, and is centered on the Appendix of this paper that compiles all Autogenous and SemiAutogenous mill installations worldwide, through the end of March 2015 Updates have(PDF) Autogenous and SemiAutogenous Mills, 2023年10月25日 Grinding accounts for more than half of the mining sector’s total energy usage, where the semiautogenous grinding (SAG) circuits are one of the main components The implementation of control and automation Machine Learning Algorithms for Semi

Application of Machine Learning for Generic Mill

2024年11月25日 This study explores the application of machine learning techniques for predicting generic mill liner wear in semiautogenous grinding (SAG) mills used in mineral processing Various models were developed and 2016年6月6日 Many of these mills operate at higher mill speeds (nominally 90% of critical speed) and often use “grid” liners to form an autogenous liner surface These mills typically grind ROM ore in a single stage A large example of such SAG Mill Grinding Circuit Design 911MetallurgistThe semiautogenous mill is also called SAG mill which is an acronym for semiautogenous grinding It is similar to an autogenous mill but uses grinding media like a ball mill grinderIt takes material itself as the main grinding media and Semi Autogenous Mill SAG Mills For Sale ball 2015年1月1日 This paper discusses, and is centered on the Appendix of this paper that compiles all Autogenous and SemiAutogenous mill installations worldwide, through the end of March 2015(PDF) Autogenous and SemiAutogenous Mills,

Semiautogenous grinding (SAG) mill liner design and

2024年9月24日 Semiautogenous grinding mills (SAG mills) are tumbling mills that most commonly have a shell diametertolength ratio of around two With this high aspect ratio, SAG mills constant mill speed, ball trajectories should degrade (ie, balls fall more towards the bulk of the charge than the toe)2017年7月29日 supported grinding mills up to the largest sizes SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll SAG and ball mill for gold ore grinding One of three SAG mills with 975 m diameter and 2 x 4000 kW drive power These mills operate in conjunction with ball mills for iron ore grinding in IranAutogenous mills, semiautogenous mills and ball mills The filling rate of steel ball in the shell of the semiautogenous mill is a main item to distinguish SAG mill and autogenous mill In order to eliminate the impact of the accumulation of rock, the autogenous mill allows to add about 3% of the ball (Φ80 ~ Φ120), SAG mill steel ball filling is generally 8% ~ 12%, even up to 15%Semi Autogenous Grinding (SAG) Mill For Sale, Sag MiningThough this section is specific to autogenous and semiautogenous mills, many of the concepts are general and apply to any form of comminution There is a continuum where one type of The coarse transfer size to the ball mill makes this circuit unsuitable for most finegrinding applications such as gold ores with 100 µm P 80Autogenous and Semiautogenous Grinding Circuits

.jpg)

Autogenous and SAG SemiAutogenous Mill Design Calculations

2018年4月17日 Mill Sizing: After laboratory and pilot plant testing confirm the feasibility of autogenous or semiautogenous grinding, it can be used to establish the exact grinding circuit and mill sizeIn the pilot plant tests, the tare power of the pilot plant mills should be determined before and after each test run The tare power should be for the empty mill2020年1月1日 Fig 1 Westwood grinding circuit 21 Semiautogenous mill model The grinding process in a SAG mill as described by Sbárbaro (2010) is Systematic calibration of a simulated semiautogenous/ballmill grinding circuit EM PérezGarcÃa ∗ J Systematic calibration of a simulated semiautogenous/ballmill 2024年7月24日 RoM Ball mills, like SAG mills, utilise coarse rocks in the RoM feed as grinding media but with 25 – 40% steel balls added, which is advantageous when the coarse fraction in the RoM feed is RoM BALL MILLS A COMPARISON WITH AG/SAG 2009年1月1日 The mass of grinding media inside the chamber is determined by a mass balance considering the ball replacement rate and the metal consumption rate, this latter parameter being proportional to the mass of mineral in the mill (Salazar et al, 2004): (12) d W b d t = F bβ (W + W b) where W b is the ball mass (t) in the mill, F b the ball Dynamic modelling and simulation of semiautogenous mills

PARAMETER OPTIMIZATION OF LARGE SAG MILL LINER

2021年6月17日 Abstract The authors analyze the influence of the semiautogenous (SAG) mill parameters on the mill grinding efficiency, energy consumption and the tangential cumulative contact energy This paper provides a new liner parameter design and optimization method, which offers theoretical guidance for the optimization design of liner parametersDOI: 101016/JMINENG201601015 Corpus ID: ; Modelling the influence on power draw of the slurry phase in Autogenous (AG), Semiautogenous (SAG) and ball mills @article{Morrell2016ModellingTI, title={Modelling the influence on power draw of the slurry phase in Autogenous (AG), Semiautogenous (SAG) and ball mills}, author={Stephen Morrell}, Modelling the influence on power draw of the slurry phase in Autogenous Largediameter autogenous and semiautogenous grinding mills represent the primary thrust of the expanding grinding technology In spite of initial difficulties, large autogenous and semiautogenous mills have reached an acceptable level of technology that provides the mineral engineer with a reliable, low cost means of ore comminutionA successful milling installation Semiautogenous mill liners: Designs, alloys, and maintenance procedures SAG mills, or SemiAutogenous Grinding mills, use a combination of steel balls and rock particles to grind ore They are larger in size and are capable of grinding larger quantities of ore than AG mills As a ball mills supplier with 22 years of experience in the grinding industry, we can provide customers with types of ball mill, vertical SAG vs AG Mills: Understanding the Key Differences ball mills

.jpg)

Autogenous and SemiAutogenous Mills ScienceDirect

2016年1月1日 The designs of autogenous and semiautogenous (SAG) grindings mills are described followed by the description of their methods of operation in grinding circuits involving crushers and ball mills Methods of estimating SAG mill volumes, mill charges, feed size and power consumptions and optimum speeds of rotation during operation are described The 2007年8月1日 SAG mill liner development draws primarily on practical experience from SAG milling operations supported by computerbased modeling of charge motion in SAG mills and on established good design practice Liner design needs to respond to the process aspects of mill liner action that are critical to good SAG mill performance, ie, the impact of shell liners on the Semiautogenous grinding (SAG) mill liner design and 2007年8月1日 For instance, semiautogenous (SAG) mills are now widely used in mining machinery as highly crucial equipment, and the replaceable wearresistant surface in SAG mills are provided by mill liners Semiautogenous grinding (SAG) mill liner design and development2018年9月25日 The model output variables are: powerdraw, load level, ball load, mineral discharge rate and size distribution, water discharge rate, ball throughput, bearing pressure, pebble throughput, and toe and shoulder angles of the internal load Advanced Simulation for SemiAutogenous Mill S ystems: A Simplified Models Approach 149Advanced Simulation for SemiAutogenous Mill Systems:

%3C1PGHL[2}HK_]YT.jpg)

SAG Mill Liner Design 911Metallurgist

2016年6月6日 As with rod and ball mills liner designs for autogenous and semiautogenous mills have been in a state of flux for a number of years Operators continually search for optimum designs Each mill application and each liner material coupled with varying mill diameters will produce a different internal wear patternSemiautogenous mills use a mix of balls and larger rocks or ore fragments as grinding media The ore is fed into the mill through a hollow trunnion at the feed end of the mill As the mill rotates, the grinding media crushes the ore particles against each other or against the ore itself, thus breaking the ore into smaller particles What is a SemiAutogenous Mill? ball mills supplier2019年10月4日 In the present work, vibration, acoustic and thermal signals were correlated to the semiautogenous grinding mill working parameters such as total power and inlet water flow rate, and then these parameters were monitored using vibration, acoustic and thermal analyses Next, the influential controlling parameters were obtained to monitor the mill conditions via Experimental Analysis of Semiautogenous Grinding Mill2023年11月28日 A particle scale model based on a full twoway coupling of the Discrete Element Method (DEM) and Smoothed Particle Hydrodynamics (SPHs) methods is applied to SAG mills Motion and collisions of resolved coarser ScaleUp Investigation of a Pilot and Industrial

.jpg)

Operation Analysis of a SAG Mill under Different Conditions Based on

2020年10月9日 As one of the machines widely used in mining, a semiautogenous grinding (SAG) mill can significantly improve the roughing efficiency of rock2018年4月9日 If semiautogenous grinding is indicated, the source for, and cost of, obtaining high quality balls in the 100 mm to 125 mm size range should be reviewed The grinding balls used in semiautogenous mills must be of top quality so that they will not break from the impact forces encountered in primary semiautogenous millsAutogenous and SemiAutogenous Grinding Mill Testing2016年4月1日 If one looks back over the last 70 years or so there is a fairly common theme to most of tumbling mill power draw models (Bond, 1961, Hogg and Fuerstenau, 1972, Arbiter and Harris, 1982, Austin, 1990)This is that the models used the charge shape shown in Fig 1 in which it was assumed that all particles moved with same rotational rate and that the slurry Modelling the influence on power draw of the slurry phase in Autogenous 2010年9月7日 performance of a typical SAG mill design (LID = 05) with that of a representative FAG mill with LID = 2 It is assumed that the reader is familiar with the concepts and symbolism of construction of mill models (1) Mill models The basic mass balance ball mills Several recent papers by It is assumed that this type of mill (59)A General Model for Semiautogenous and Autogenous

(PDF) A new autogenous and semiautogenous mill model

2004年3月1日 The model is equally applicable to ball, semiautogenous and autogenous mills and contains a description of the power draw of both the cylindrical section and the coneends2016年4月1日 Figure 9 – Measured vs Predicted Power Draws of Mills SAG Mills with Slurry Pools – Assumption in model (equation 1) is that there is no slurry pooling and θtp = θtm "Modelling the influence on power draw of the slurry phase in Autogenous (AG), Semiautogenous (SAG) and ball mills"Modelling the influence on power draw of the slurry phase in Autogenous Mill filling is an important operational parameter in a SAG mill circuit and by its control and optimisation it can produce significant improvements in production capacity and energy efficiency However, it is industry practice to report mill load as the total output given by load cells, or kPa for systems based on lubrication bearing back pressure, rather than the actual percent total mill Optimisation of a Semiautogenous Grinding Mill through2016年6月6日 Many of these mills operate at higher mill speeds (nominally 90% of critical speed) and often use “grid” liners to form an autogenous liner surface These mills typically grind ROM ore in a single stage A large example of such SAG Mill Grinding Circuit Design 911Metallurgist

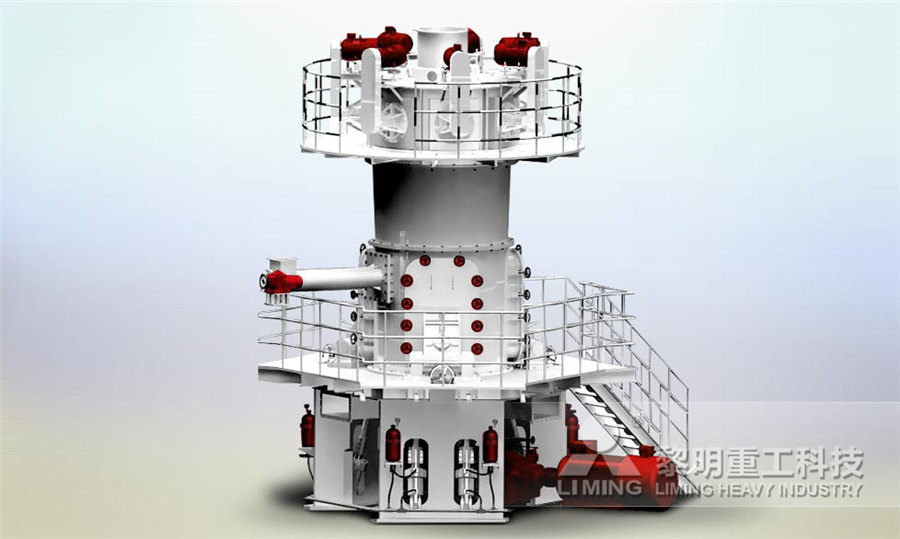

Semi Autogenous Mill SAG Mills For Sale ball

The semiautogenous mill is also called SAG mill which is an acronym for semiautogenous grinding It is similar to an autogenous mill but uses grinding media like a ball mill grinderIt takes material itself as the main grinding media and 2015年1月1日 This paper discusses, and is centered on the Appendix of this paper that compiles all Autogenous and SemiAutogenous mill installations worldwide, through the end of March 2015(PDF) Autogenous and SemiAutogenous Mills, 2024年9月24日 Semiautogenous grinding mills (SAG mills) are tumbling mills that most commonly have a shell diametertolength ratio of around two With this high aspect ratio, SAG mills constant mill speed, ball trajectories should degrade (ie, balls fall more towards the bulk of the charge than the toe)Semiautogenous grinding (SAG) mill liner design and 2017年7月29日 supported grinding mills up to the largest sizes SAG/ball mill circuit incorporating pebble crushers and a POLYCOM® highpressure grinding roll SAG and ball mill for gold ore grinding One of three SAG mills with 975 m diameter and 2 x 4000 kW drive power These mills operate in conjunction with ball mills for iron ore grinding in IranAutogenous mills, semiautogenous mills and ball mills

.jpg)

Semi Autogenous Grinding (SAG) Mill For Sale, Sag Mining

The filling rate of steel ball in the shell of the semiautogenous mill is a main item to distinguish SAG mill and autogenous mill In order to eliminate the impact of the accumulation of rock, the autogenous mill allows to add about 3% of the ball (Φ80 ~ Φ120), SAG mill steel ball filling is generally 8% ~ 12%, even up to 15%Though this section is specific to autogenous and semiautogenous mills, many of the concepts are general and apply to any form of comminution There is a continuum where one type of The coarse transfer size to the ball mill makes this circuit unsuitable for most finegrinding applications such as gold ores with 100 µm P 80Autogenous and Semiautogenous Grinding Circuits2018年4月17日 Mill Sizing: After laboratory and pilot plant testing confirm the feasibility of autogenous or semiautogenous grinding, it can be used to establish the exact grinding circuit and mill sizeIn the pilot plant tests, the tare power of the pilot plant mills should be determined before and after each test run The tare power should be for the empty millAutogenous and SAG SemiAutogenous Mill Design Calculations2020年1月1日 Fig 1 Westwood grinding circuit 21 Semiautogenous mill model The grinding process in a SAG mill as described by Sbárbaro (2010) is Systematic calibration of a simulated semiautogenous/ballmill grinding circuit EM PérezGarcÃa ∗ J Systematic calibration of a simulated semiautogenous/ballmill

RoM BALL MILLS A COMPARISON WITH AG/SAG

2024年7月24日 RoM Ball mills, like SAG mills, utilise coarse rocks in the RoM feed as grinding media but with 25 – 40% steel balls added, which is advantageous when the coarse fraction in the RoM feed is