Problems in the construction of calcium carbonate grinding plant

Grinding calcium carbonate: techniques, challenges

High abrasion: Calcium carbonate is an abrasive mineral, which causes rapid wear to grinding equipment This requires careful selection of the materials of construction of the machines to prolong their life Granulometry control: 2023年6月15日 Currently, the primary problems in the indirect manufacture of calcium carbonate from the industrial byproduct gypsum are additive recycling and process simplification This Progress in the Preparation of Calcium Carbonate by Indirect 2023年4月26日 This includes aluminosilicate pretreatment methods (drying, grinding, and calcining) to increase the precursor's reactivity and degree of amorphization, alkali activation A review: Alkaliactivated cement and concrete ScienceDirect2017年1月1日 Calcination, dissolution and precipitation experiments were carried out under various conditions including: calcination temperature (800, Precipitated Calcium carbonate production, synthesis

.jpg)

Case study for production of calcium carbonate from carbon

2016年6月1日 In this work, a concept for producing calcium carbonate from argon oxygen decarburisation (AOD) slag was further developed In addition, its economic and 2024年5月24日 The new technology of microbially induced calcium carbonate precipitation (MICP) has been applied in construction materials as a strategy to enhance their properties In Comparison of calcium carbonate production by bacterial isolates 2021年1月12日 Cold sintering of synthesized nanosized vaterite, another form of calcium carbonate, in aqueous and oil media has been explored and reported to have more desirable mechanical properties compared to conventional Cold Sintering of Calcium Carbonate for Construction 2024年1月19日 As a promising approach for CO 2 reduction, waste management, and resource recovery, we addressed the opportunities and challenges associated with advancing CCUS through the utilisation of(PDF) Maximising the benefits of calcium carbonate in

.jpg)

CALCIUM CARBONATE (GCC) Hosokawa Alpine

The production of calcium carbonate fillers (GCC) from chalk, limestone or marble is challenging today GCC stands for dry powder or a suspension and is indispensable in2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy Calcium Carbonate Grinding Production Line TAYMACHINERY2023年6月17日 The oyster shell is a residue rich in calcium carbonate, which can be reused as a raw material for creating building materials For this reason, many researchers focused on the incorporation of Potential Use of Oyster Shell Waste in the Composition

Progress in the Preparation of Calcium Carbonate by Indirect

2023年6月15日 To avoid the longterm pollution of land and water by industrial gypsum byproducts, the exploitation of this resource has become a priority The indirect synthesis of calcium carbonate from the industrial byproduct gypsum has received substantial attention as a viable method for resource utilization Currently, the primary problems in the indirect manufacture of China Calcium Carbonate Plant wholesale 140 T/H Lime Grinding Plant Calcium Carbonate Grinding Plant US$ / Set 1 Set (MOQ) Henan Zhengzhou Mining Machinery Co, Ltd Construction Machinery Plant; Complete Plant; Calcium Carbonate Plant Price;Calcium Carbonate Plant MadeinChinaCalcium carbonate functions as an agricultural amendment, raising the pH level in acidic soils and supplying calcium essential for plant growth Papermaking Calcium carbonate acts as a coating and filler agent in the paper and pulp industry, enhancing paper’s brightness, opacity, and suitability for printingCalcium Carbonate: Grinding and Applications Overview2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or organic resin affects the dispersion of the minerals and ultimately downstream product properties in consumer industries such as paint, Effects of Grinding Aids Used in Grinding Calcium Carbonate (CaCO3

R)8OC`6F[ZIB.jpg)

The Ultimate Guide Calcium Carbonate Manufacturing Process

2024年8月21日 The Ultimate Guide to Calcium Carbonate Manufacturing Process Have you ever wondered how Calcium Carbonate is produced on an industrial scale? The Calcium Carbonate Manufacturing Process is a fascinating journey that involves various steps to transform raw materials into the versatile compound we all know and use in our daily lives2024年1月19日 With the recognised reactive role of calcium carbonate in PC, there is a growing interest in harnessing various forms of calcium carbonate to enhance the performance of different cement typesMaximising the benefits of calcium carbonate in sustainable 2023年7月10日 Cement manufacturing is a significant industrial activity that plays a vital role in the construction sector However, the process of cement production is associated with various environmental Cement Manufacturing Process and Its Environmental Impact2021年4月1日 The objective of the present study is to obtain white waterborne paint using calcium carbonate as filler, a waste results from Romanian plant fertilizer manufacturing(PDF) Advanced recovery of calcium carbonate

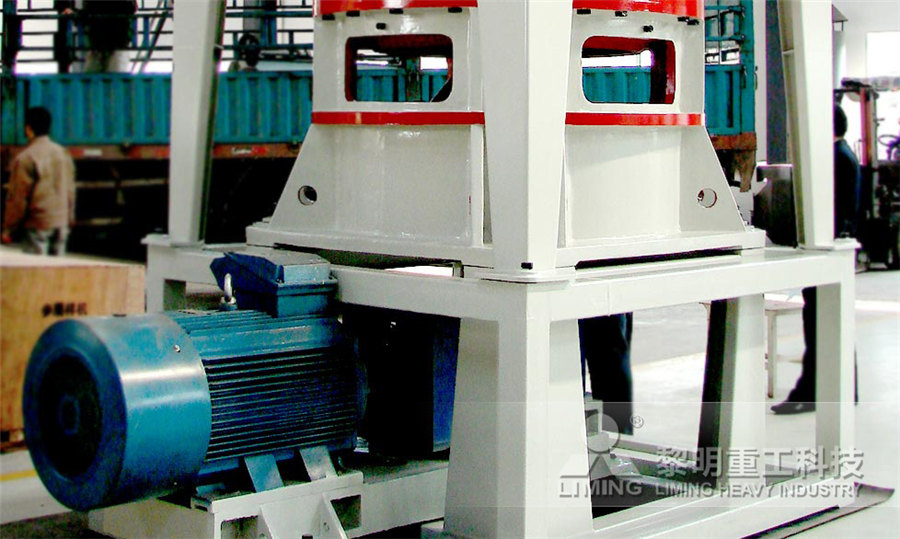

grinding equipment for calcium carbonate process CM

27 Sep 2023; Grinding equipment for calcium carbonate is essential in the process of producing fine and ultrafine calcium carbonate powder Calcium carbonate grinding equipment mainly includes ball mill, Raymond mill, vertical roller mill, and ultrafine millThese grinding equipment are widely used in various fields of mining, construction, metallurgy, chemical industry, and so onCalcium carbonate exists in the earth’s crust in such natural forms as chalk, limestone and marble Undeniably one of the most prevalent compounds on earth, calcium carbonate has proven valuable in a variety of industries The Calcium Carbonate Grinding Union ProcessHigh abrasion: Calcium carbonate is an abrasive mineral, which causes rapid wear to grinding equipment This requires careful selection of the materials of construction of the machines to prolong their life Granulometry control: Achieving a uniform granulometry adapted to the specific needs of applications can be complex Precise control of grinding parameters, such as rotation Grinding calcium carbonate: techniques, challenges and calcium carbonate requirements in rotary kilns in Lebda cement plant at different operational parameters such as total calcium carbonate Wt % as a raw material and fuel consumption in order to Optimization of Calcium Carbonate Requirements in Rotary Kilns

Calcium Carbonate Ball Mill Plant DASWELL

We are a calcium carbonate ball mill plant factory with over 30 years of work experience in this industry, and are at the leading domestic level in the grinding and grading technology of ball mills We can screen and evaluate the raw materials to see if the raw materials can meet the requirements of ball mill production900 to 1050 °C: Decomposition of remaining calcium carbonate to calcium oxide and CO2 1300 to 1450 °C : Partial melting facilitates the reaction of belite into alite, forming clinker Clinker Formation : The sintering process aggregates the materials into nodules, typically 1–10 mm in diameter, known as clinkerStepbyStep Guide to the Manufacturing of Cement PRACTICAL 2024年6月14日 GCC VS PCC and Calcium Carbonate Grinding Mills ; CLUM Series Mill: EcoFriendly and EnergySaving, Leading UltraFine Powder Production to New Height ; Efficient Grinding Of Calcium Carbonate Calcium Oxide: HGM125 Ultrafine Grinding Mill in Liaoning Ground Calcium Carbonate Production Plant In Sichuan2015年8月5日 The main use of calcium carbonate is in the construction industry, CaCO3 processing Plant contains CaCO3 Calcium Carbonate crushing plant and CaCO3 Calcium Carbonate grinding plant >> Jaw crusher: output fineness 10105mm, capacity 90t/h >> Hammer crusher: output fineness smaller than 25mm, capacity 45t/hCaCO3 Calcium Carbonate Processing Plant

.jpg)

How to Choose a Calcium Carbonate Grinding Mill DASWELL

The choice of grinding mill machine is related to the quality of the final ground calcium carbonate powder, so how to choose the right calcium carbonate grinding equipment has also become a concern for many customers This article will provide you with some suggestions Production method of calcium carbonate powder2015年7月1日 It is shown that calcium carbonate has an accelerating effect on C3S and cement hydration and leads to the precipitation of some calcium carbosilicate hydrate View Show abstract(PDF) Effect of Calcium Carbonate Replacement on 2024年1月19日 Effect of calcium carbonate addition on the compressive strength of different types of cements 12,1921,2426,7890 These cements are shown in the subfigures: a Portland cement, b blended (PDF) Maximising the benefits of calcium carbonate in 2024年10月2日 Calcium carbonate microspheres fabricated through coprecipitation regulated by soluble starch can be used as drug carriers for plants (Xiang et al, 2018) Porous calcium carbonate microspheres with intercalated Improvements in the utilization of calcium carbonate

.jpg)

Calcium Carbonate Plant Manufacturers Suppliers in India

Accurate Calcium Plant Ask Price Calcium is an essential plant nutrient required for growth and development of plant, especially the root and shoot tip Ca2+ is an important divalent cation and is required for structural roles in the cell wall and membranes where it exists as Ca2+ pectateCalcium carbonate is one of the most used raw materials in various industries, such as construction materials, food supplement, pharmaceutics, animal feed, plastic production, and others Calcium carbonate can derive from marine wastes, like crustaceans and bivalve’s shells The worldwide demand for new sources of food has increased exponentially, and following The Potential Use of Oyster Shell Waste in New ValueAdded By1Plant Nutrition Dept and 2Soil and Water Resource Dept, Agriculture and Biological Division, National Research Centre, 33 El Buhouth St, 12622, in which a high amount of calcium carbonate dominates the problems related to agricultural land use They are characterized by the presence of calcium carbonate in the parent material and by aSome Characteristics of Calcareous soils A reviewIntroduction of Calcium Carbonate Grinding Mill Calcium Carbonate Grinding Mill is the main equipment during the calcium carbonate powder making plant, which is suitable for grinding calcium carbonate into As no rolling bearings or screws in grinding cavity, there are no problems caused by bolts shedding or rapid wear of bearings and seal Calcium Carbonate Grinding Mill Henan Turui Machinery Co, Ltd

.jpg)

Numerical Modelling of the Calcination Process in a Cement

calcium carbonate decomposition into calcium oxide (CaO) and carbon dioxide (CO2), typically occurring at a temperature around 850900°C As the calcination is an endothermic reaction (~17 MJ/kgCaCO3), fuel is combusted in the calciner In the rotary kiln, the remaining calcination is completed and clinker is formed2022年3月8日 Calcium Carbonate in the Concrete Industry Calcium carbonate is found in three principal rock types: chalk, limestone, and dolomite (including the metamorphic rock known as dolomitic marble) Limestone and lime are the principal calcium carbonate derivatives used in the concrete industry Calcium carbonate helps accelerate the cure rate of Calcium Carbonate in the Concrete Industry Noah Chemicals2021年10月15日 In practice, the PCC product with the different polymorphs (ie, calcite, vaterite, and aragonite) and unique morphology may be synthesized from the mixing of solutions containing calcium ion and carbonate ion depending on the different processing conditions [6], [7], [8]Because of the most stable phase at room temperature, calcite may be easily formed and The potential use of green mussel ( Perna Viridis ) shells for 2020年2月18日 Limestone is a fundamental raw material in various industrial sectors It is formed due to biochemical precipitation of calcium carbonate, and further compaction over long periods of time(PDF) Environmental Hazards of Limestone Mining

.jpg)

Calcium Carbonate Grinding Production Line TAYMACHINERY

The calcium carbonate grinding production line is an efficient, stable, and reliable production line with wide application prospects By using advanced equipment and technology, this production line is able to produce highquality calcium carbonate powder to meet the needs of different industries At the same time, the production line also has the advantages of energy 2023年6月17日 The oyster shell is a residue rich in calcium carbonate, which can be reused as a raw material for creating building materials For this reason, many researchers focused on the incorporation of Potential Use of Oyster Shell Waste in the Composition 2023年6月15日 To avoid the longterm pollution of land and water by industrial gypsum byproducts, the exploitation of this resource has become a priority The indirect synthesis of calcium carbonate from the industrial byproduct gypsum has received substantial attention as a viable method for resource utilization Currently, the primary problems in the indirect manufacture of Progress in the Preparation of Calcium Carbonate by Indirect China Calcium Carbonate Plant wholesale 140 T/H Lime Grinding Plant Calcium Carbonate Grinding Plant US$ / Set 1 Set (MOQ) Henan Zhengzhou Mining Machinery Co, Ltd Construction Machinery Plant; Complete Plant; Calcium Carbonate Plant Price;Calcium Carbonate Plant MadeinChina

.jpg)

Calcium Carbonate: Grinding and Applications Overview

Calcium carbonate functions as an agricultural amendment, raising the pH level in acidic soils and supplying calcium essential for plant growth Papermaking Calcium carbonate acts as a coating and filler agent in the paper and pulp industry, enhancing paper’s brightness, opacity, and suitability for printing2021年12月31日 Grinding aid chemicals which are used in the grinding of calcium carbonate (CaCO3) to prevent agglomeration are chemisorbed on the surfaces of particles, and the compatibility of them with the solvent, water, or organic resin affects the dispersion of the minerals and ultimately downstream product properties in consumer industries such as paint, Effects of Grinding Aids Used in Grinding Calcium Carbonate (CaCO3 2024年8月21日 The Ultimate Guide to Calcium Carbonate Manufacturing Process Have you ever wondered how Calcium Carbonate is produced on an industrial scale? The Calcium Carbonate Manufacturing Process is a fascinating journey that involves various steps to transform raw materials into the versatile compound we all know and use in our daily livesThe Ultimate Guide Calcium Carbonate Manufacturing Process2024年1月19日 With the recognised reactive role of calcium carbonate in PC, there is a growing interest in harnessing various forms of calcium carbonate to enhance the performance of different cement typesMaximising the benefits of calcium carbonate in sustainable

.jpg)

Cement Manufacturing Process and Its Environmental Impact

2023年7月10日 Cement manufacturing is a significant industrial activity that plays a vital role in the construction sector However, the process of cement production is associated with various environmental